I have heard several members who (whom) make their own parts, speak of a brand of printer paper where they copy the plan or part onto said paper and then peel the print and place on their wood. After tracing or cutting the paper is peeled off and the piece (part) is used in construction. Can anyone tell me the name brand of the paper in question? Am I imagining this? when I asked the kid at the big box paper supply store, he looked at me as if I had two heads. Any help or suggestions in tracing or copying parts is welcomed

copying/tracing parts

7 posts

• Page 1 of 1

copying/tracing parts

All;

I have heard several members who (whom) make their own parts, speak of a brand of printer paper where they copy the plan or part onto said paper and then peel the print and place on their wood. After tracing or cutting the paper is peeled off and the piece (part) is used in construction. Can anyone tell me the name brand of the paper in question? Am I imagining this? when I asked the kid at the big box paper supply store, he looked at me as if I had two heads. Any help or suggestions in tracing or copying parts is welcomed

I have heard several members who (whom) make their own parts, speak of a brand of printer paper where they copy the plan or part onto said paper and then peel the print and place on their wood. After tracing or cutting the paper is peeled off and the piece (part) is used in construction. Can anyone tell me the name brand of the paper in question? Am I imagining this? when I asked the kid at the big box paper supply store, he looked at me as if I had two heads. Any help or suggestions in tracing or copying parts is welcomed

- Daniel

- Posts: 2

- Joined: Thu Jan 19, 2006 7:44 pm

- Location: North of Boston

Re: copying/tracing parts

two or three ways to do it.

Print your parts out Scanning from the Plans as PDF which respects scale

If you are using a laserjet or a xerox phaser printer...

Place the paper face down on the wood. and use a hot iron to transfer the waxy image to the wood.

If its a standard ink jet you can use acetone in the same way but without the iron.

The easiest is to print off the PDF scan of the parts and use white glue or a glue stick to affix the image to the wood, sand the paper off.

You COULD print the image onto carbon paper and press the carbon transfer onto the wood but that is doing things the HARD and very old school way.

Print your parts out Scanning from the Plans as PDF which respects scale

If you are using a laserjet or a xerox phaser printer...

Place the paper face down on the wood. and use a hot iron to transfer the waxy image to the wood.

If its a standard ink jet you can use acetone in the same way but without the iron.

The easiest is to print off the PDF scan of the parts and use white glue or a glue stick to affix the image to the wood, sand the paper off.

You COULD print the image onto carbon paper and press the carbon transfer onto the wood but that is doing things the HARD and very old school way.

- joecrouse

- Posts: 216

- Joined: Mon May 23, 2011 9:20 am

Re: copying/tracing parts

I have had good results by using Scotch Brand Restickable Glue Sticks. Just cut out your printed pattern and coat with glue, allow to dry and stick to the wood. After cutting your part out just peel off the pattern. It does not leave a residue on the wood. The glue is the same as used on post it notes.

You can do it if you have patience!

- Walt

- Posts: 12

- Joined: Sat Jun 24, 2006 4:36 pm

- Location: Westminster, California, USA

Re: copying/tracing parts

Make copies of the plan on a photocopier. Turn the copy over face down on the wood. Take Xylol and rub the back of the paper to transfer the parts onto the wood. Xylol can be found at any hardware store and works better than Acetone and is the base for Chartpak markers. Use a Chartpak Blender marker for best control. There are probably as many ways to create parts as there are modelers making them. you will find the one that is best for you.

Good Luck!

Steve

Good Luck!

Steve

- Steve Blanchard

- Posts: 343

- Joined: Tue Jun 14, 2011 10:08 am

Re: copying/tracing parts

This may sound unorthodox, but I knock parts out really quickly using this method. I don't need to print a set of part cutting templates, and it doesn't even destroy the original plan. I place the wood under the plan, score the plan with a dull exacto with the wood underneath to make and imprint, and then fully cut out the parts with a sharp exacto. The dull exacto blade will not cut through the plan, but will leave a good imprint on the wood. The method helps me knock out no-plans scratchbuilds in record time, using 3-view and hand sketched drawings.

You do not have the required permissions to view the files attached to this post.

- Bill Gaylord

- Posts: 904

- Joined: Sun Nov 09, 2008 1:29 pm

- Location: Grove City PA

Re: copying/tracing parts

I have been making my own parts recently. Its not too difficult. AND you can scale the model to ANY size you want...

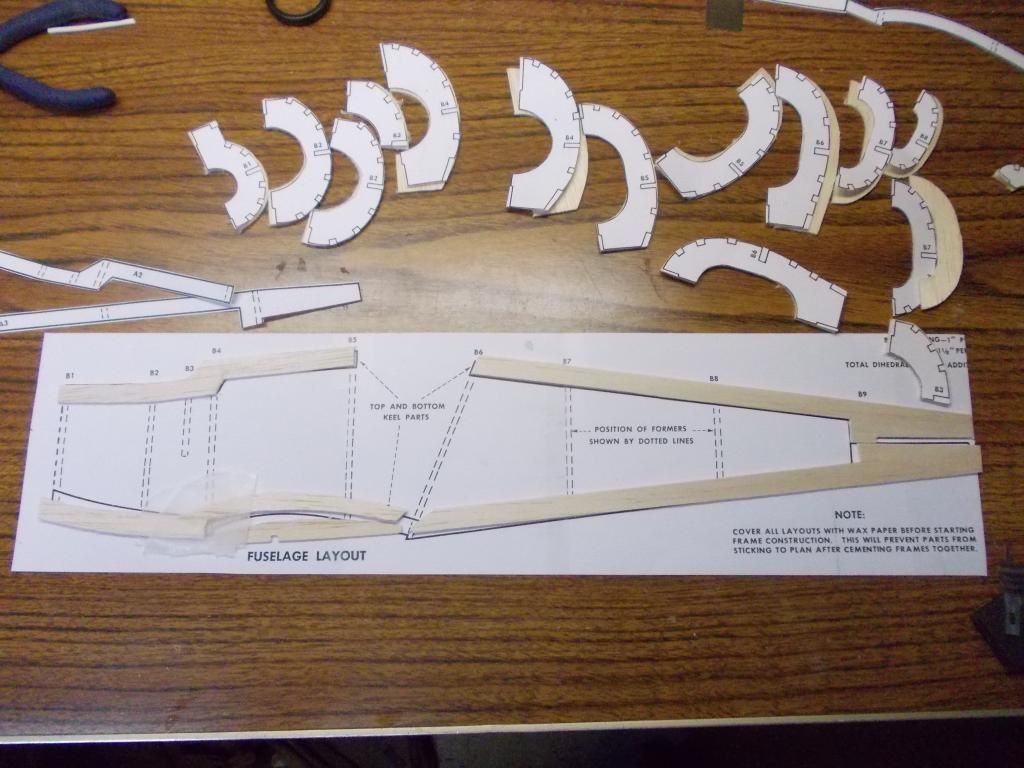

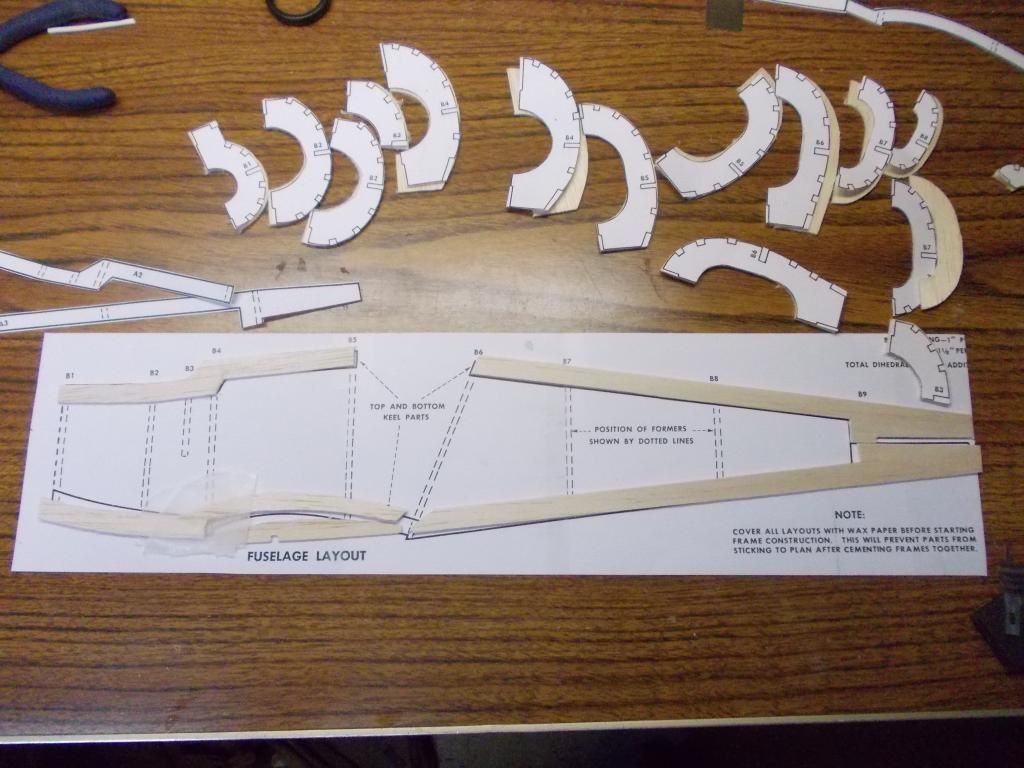

My recent projects are remaking the 100 series just a bit bigger... here are the frames for the Pfalz I am working on...

I just scale up to what I want, cut out 2 of each frame. Lay them out on hand selected 1/16 stock and rough cut. Then I just hold the paper in place and sand to shape with my Dremel sander.

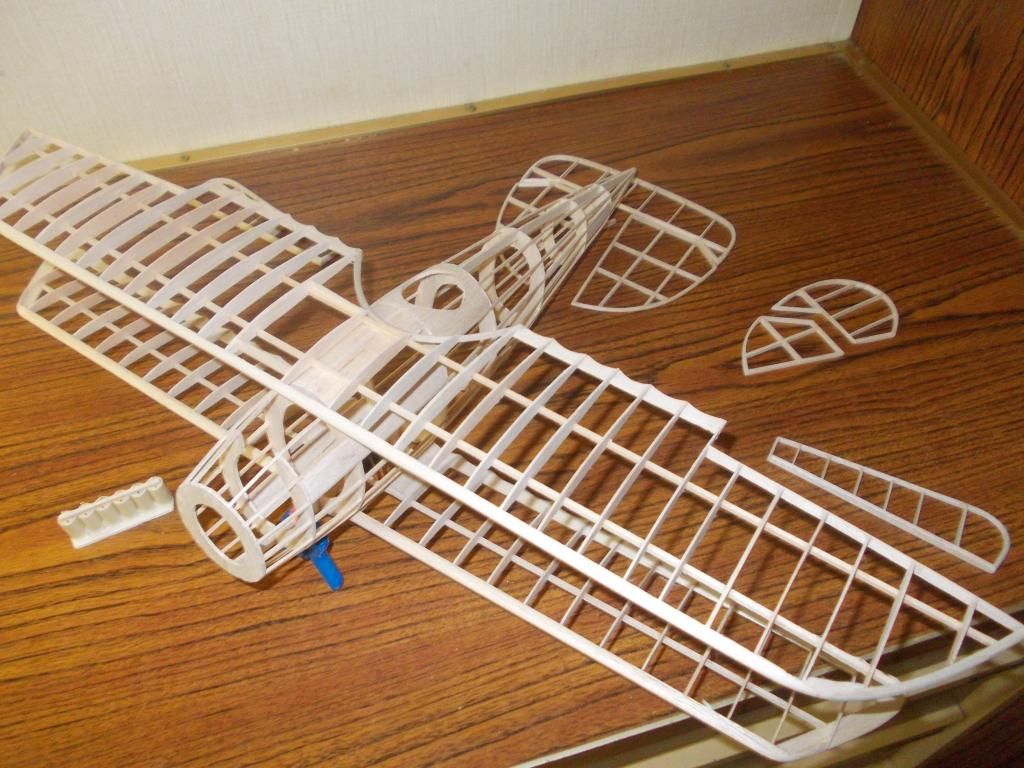

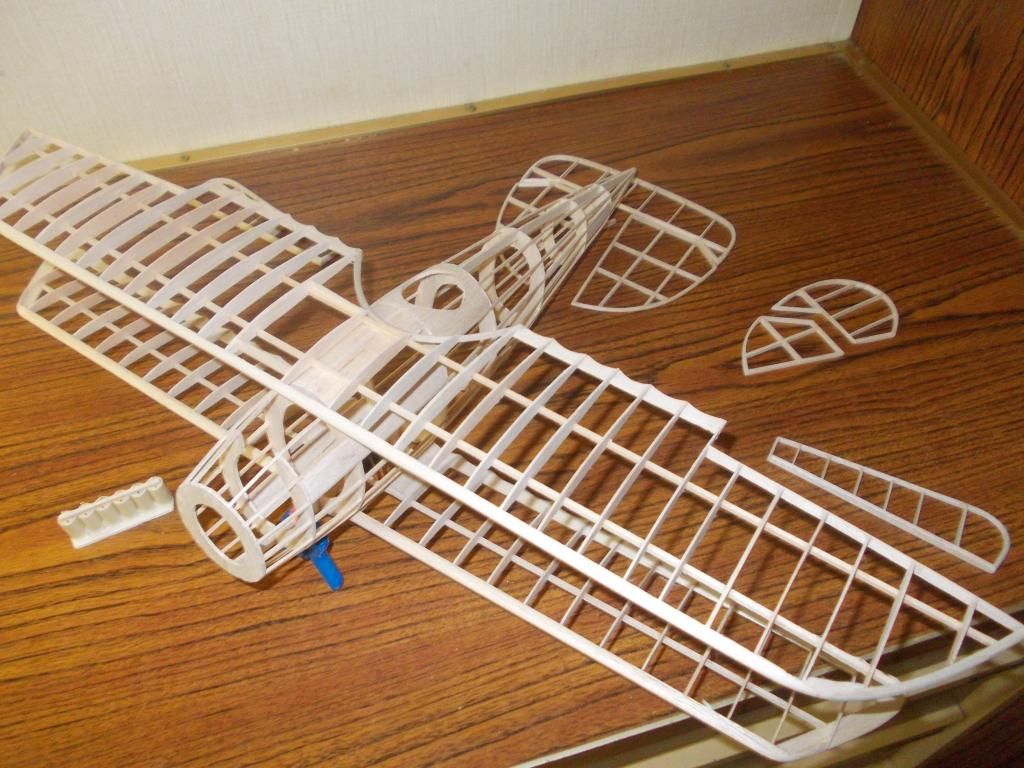

Here is a pic of the skeleton of the Albatros built the same way... The wing ribs are 1/32...

Mitch

My recent projects are remaking the 100 series just a bit bigger... here are the frames for the Pfalz I am working on...

I just scale up to what I want, cut out 2 of each frame. Lay them out on hand selected 1/16 stock and rough cut. Then I just hold the paper in place and sand to shape with my Dremel sander.

Here is a pic of the skeleton of the Albatros built the same way... The wing ribs are 1/32...

Mitch

- Mitch

- Posts: 1347

- Joined: Mon Aug 22, 2011 9:16 pm

- Location: Kent, WA

Re: copying/tracing parts

Here is what I do:

Getting the parts on paper, one of two methods:

1a) Copy the plan and cut out (just like Mitch does). This works well if all the parts are nicely grouped on the plan so you only need to copy a small section of the plan. Always check your copy to make sure the copier didn't stretch the parts.

or

1b) On some plans, the parts are scattered all over the plan and you would have to make a lot of copies with just one or two parts on each. In that case I use either tracing paper or velum, and trace the part directly from the plan with a pencil by hand. I typically use a couple of small pieces of masking tape to make sure the tracing paper doesn't slip or move while I trace. I continue doing this until I have all the parts drawn on the sheet of tracing paper / vellum. This also works well on some plans where only half of the former is drawn - you draw one half, then flip the tracing paper over and then complete the other symmetrical half of the part on the other side. I then copy this velum to normal copier paper, especially if I need to make multiple copies of a given part (like wing ribs). If a one-off, you can skip that step and cut out from the tracing paper directly.

Getting it on the wood:

2) Glue it on with the cheapest water soluable glue stick you can find. Glue sticks work well, because it is a "dry" glue, so the paper doesn't deform when you stick them on. Some glue sticks have a more permanent glue - you may have difficulty getting the paper off the part afterwards, so I recommend just using the cheapest ones you can find.

3) Cut the part out with a sharp scalpel. I like to cut it just very slightly oversize and then trim perfectly with a sanding block. If you can cut very accurately, just cut it exactly to size from the beginning. With really thick wood (the stuff I use for radio control models for example) I always cut oversize and then true up with a sanding block, as I find it very difficult to cut perfectly square on something like 1/4" balsa. In the case of free-flight models it is less of a problem as we seldom use anything thicker than 1/16" or 3/32" balsa. When cutting from plywood or another hardwood, I cut it oversize with a scroll saw and then use a disk sander to sand the part perfectly to shape.

Getting the paper off the wood:

4) Lightly wet with a spunge dipped in water, and leave for about 30 sec to a minute for the water to soak into the paper and wet the glue from the glue stick underneath. You can then peel the paper off, usually without leaving any residue. If you were over zealous with the glue stick, some residue might be left on the part in which case you can just wipe it off with a wet cloth. If the wood got slightly wet, make sure you leave it flat to dry so it doesn't warp, but I never really had this problem.

There are other methods to transfer the shape to the wood, but I have used the above for scores of models over the years - sometimes on radio control models with literally hundreds of parts and I always get consistently accurate parts this way. It is probably not the quickest, but really accurate and consistent. It also leave no marks on the wood afterwards, resulting in builds that look very "clean".

Getting the parts on paper, one of two methods:

1a) Copy the plan and cut out (just like Mitch does). This works well if all the parts are nicely grouped on the plan so you only need to copy a small section of the plan. Always check your copy to make sure the copier didn't stretch the parts.

or

1b) On some plans, the parts are scattered all over the plan and you would have to make a lot of copies with just one or two parts on each. In that case I use either tracing paper or velum, and trace the part directly from the plan with a pencil by hand. I typically use a couple of small pieces of masking tape to make sure the tracing paper doesn't slip or move while I trace. I continue doing this until I have all the parts drawn on the sheet of tracing paper / vellum. This also works well on some plans where only half of the former is drawn - you draw one half, then flip the tracing paper over and then complete the other symmetrical half of the part on the other side. I then copy this velum to normal copier paper, especially if I need to make multiple copies of a given part (like wing ribs). If a one-off, you can skip that step and cut out from the tracing paper directly.

Getting it on the wood:

2) Glue it on with the cheapest water soluable glue stick you can find. Glue sticks work well, because it is a "dry" glue, so the paper doesn't deform when you stick them on. Some glue sticks have a more permanent glue - you may have difficulty getting the paper off the part afterwards, so I recommend just using the cheapest ones you can find.

3) Cut the part out with a sharp scalpel. I like to cut it just very slightly oversize and then trim perfectly with a sanding block. If you can cut very accurately, just cut it exactly to size from the beginning. With really thick wood (the stuff I use for radio control models for example) I always cut oversize and then true up with a sanding block, as I find it very difficult to cut perfectly square on something like 1/4" balsa. In the case of free-flight models it is less of a problem as we seldom use anything thicker than 1/16" or 3/32" balsa. When cutting from plywood or another hardwood, I cut it oversize with a scroll saw and then use a disk sander to sand the part perfectly to shape.

Getting the paper off the wood:

4) Lightly wet with a spunge dipped in water, and leave for about 30 sec to a minute for the water to soak into the paper and wet the glue from the glue stick underneath. You can then peel the paper off, usually without leaving any residue. If you were over zealous with the glue stick, some residue might be left on the part in which case you can just wipe it off with a wet cloth. If the wood got slightly wet, make sure you leave it flat to dry so it doesn't warp, but I never really had this problem.

There are other methods to transfer the shape to the wood, but I have used the above for scores of models over the years - sometimes on radio control models with literally hundreds of parts and I always get consistently accurate parts this way. It is probably not the quickest, but really accurate and consistent. It also leave no marks on the wood afterwards, resulting in builds that look very "clean".

B.A. Broughton

- Mfezi

- Posts: 52

- Joined: Thu Dec 24, 2009 7:58 am

- Location: Pretoria, South Africa

7 posts

• Page 1 of 1

Return to General Building Questions

Who is online

Users browsing this forum: No registered users and 36 guests