Double Trouble

21 posts

• Page 2 of 2 • 1, 2

Re: Double Trouble

Mitch, you said your not using landing gear. are you still going to use a plastic, or plywood spar where the L- gear would mount? do you think it still needs that?

- davidchoate

- Posts: 1263

- Joined: Wed Aug 14, 2013 6:41 am

- Location: PHiladelphia PA

Re: Double Trouble

I have always used that wing brace in my 400 series. I think it's primary function is a brace, It also sets the dihedral, so lately I have been cutting my own out of plywood to increase the dihedral. FAC rules allowable maximum dihedral is for the wing tip to be eye level to the bottom of the canopy.

This plane however will be different. The ws will be approx. 35 inches. I was planning on making the wing removable, as in my Mustang. I was told by a fellow FAC'er that would NOT be a good idea. Keeping the two fuselages perfectly in line with each other will be critical. His recommendation was to build the fuselages and center wing section all solid. With the tail also glued in place. This way I will have a solid box that I can make square and have the two thrust lines working together.

Getting to your question. I plan to have the two outer wing panels removable for transport. I will need to make a secure joint that will stay together in flight. I am thinking of using straws mounted into the wing, and a dowel to make the connection. Magnets to hold things in place... at least that's my idea...

I hope I answered your question... Mitch

This plane however will be different. The ws will be approx. 35 inches. I was planning on making the wing removable, as in my Mustang. I was told by a fellow FAC'er that would NOT be a good idea. Keeping the two fuselages perfectly in line with each other will be critical. His recommendation was to build the fuselages and center wing section all solid. With the tail also glued in place. This way I will have a solid box that I can make square and have the two thrust lines working together.

Getting to your question. I plan to have the two outer wing panels removable for transport. I will need to make a secure joint that will stay together in flight. I am thinking of using straws mounted into the wing, and a dowel to make the connection. Magnets to hold things in place... at least that's my idea...

I hope I answered your question... Mitch

- Mitch

- Posts: 1347

- Joined: Mon Aug 22, 2011 9:16 pm

- Location: Kent, WA

Re: Double Trouble

I had a thought when doing my Edge that it would be possible to make the wings non-permanently mounted just by strengthening or making the A-6 piece plywood, and have a screw go from inside the fuselage, through A-6, and into a blindnut in wings, but since its only 20" WS I didn't do it, but I may use it in the future.

- davidchoate

- Posts: 1263

- Joined: Wed Aug 14, 2013 6:41 am

- Location: PHiladelphia PA

Re: Double Trouble

Nice work Mitch! May I ask what items are used to check the squareness of the formers so that I may increase my tricks of the trade? Squares and triangles seem to large to fit between. A 90 degree piece of wood seems unreliable after time. Thanks ahead of time. I am getting an itch to build a twin mustang....must be contagious.

- gearz

- Posts: 3

- Joined: Mon Nov 04, 2013 5:47 pm

- Location: Yuma, AZ

Re: Double Trouble

Building the fuselage nearly square... as mine are not perfect either...

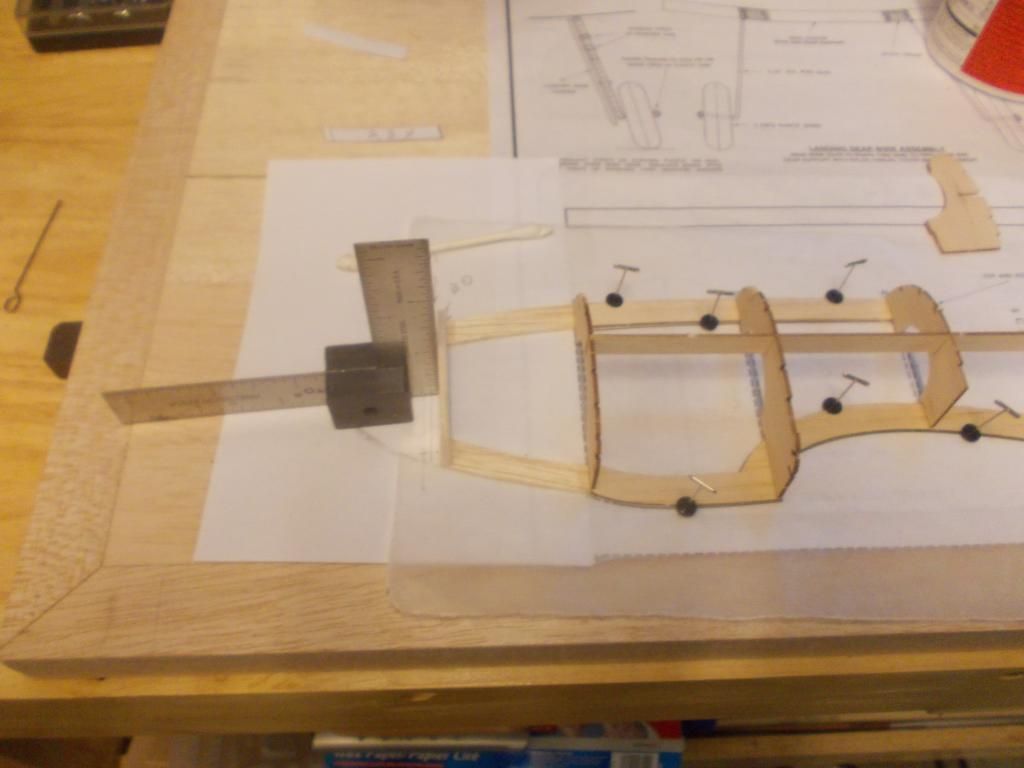

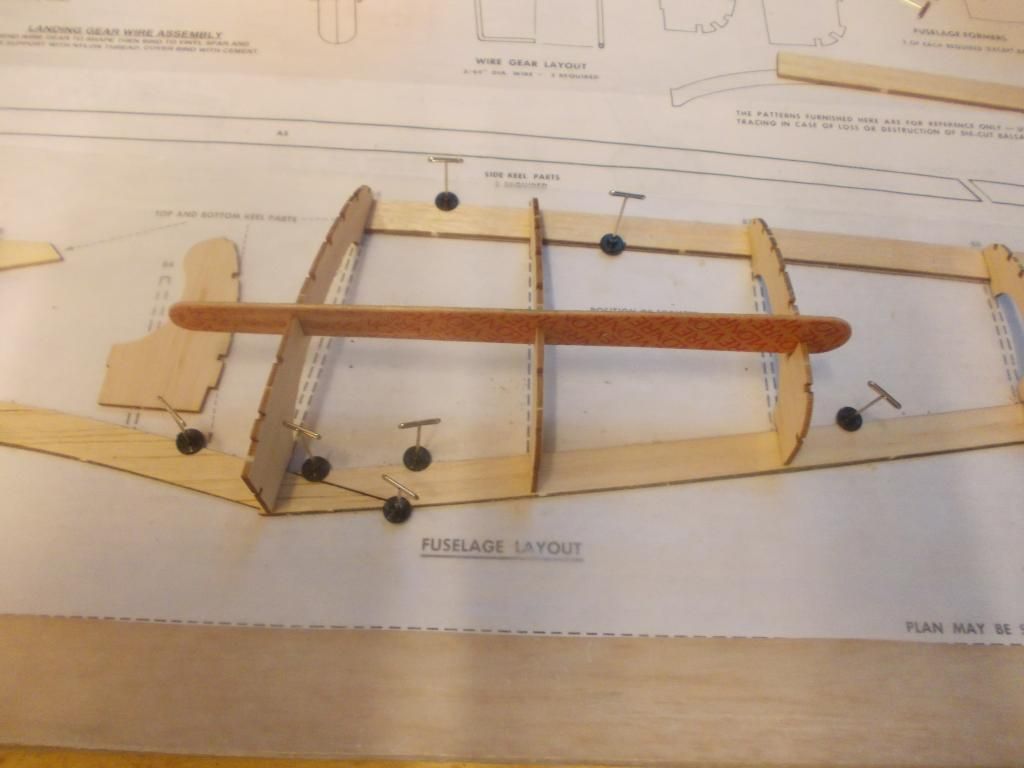

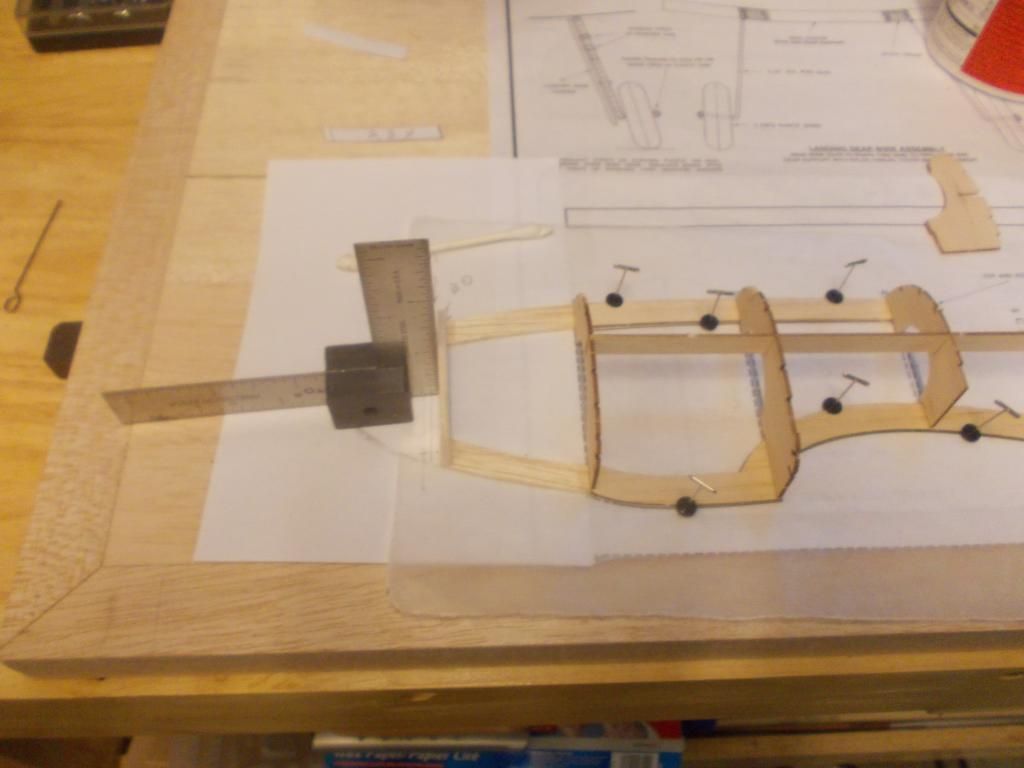

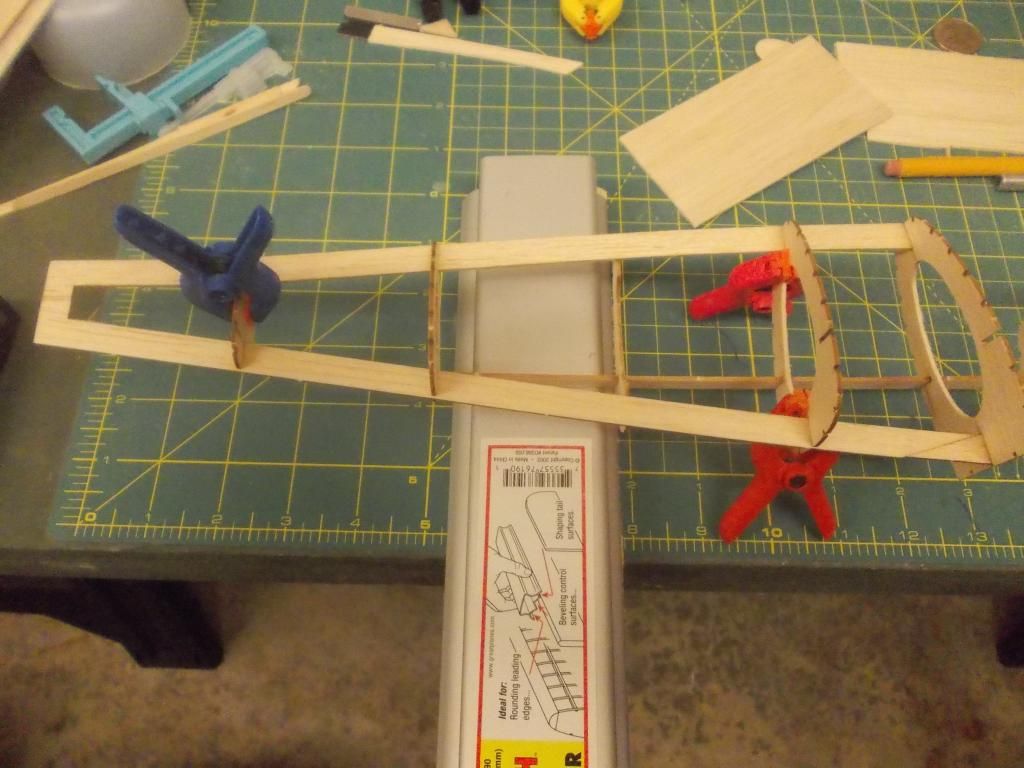

I use a few different ways to easily check for square. First I use an X-Acto square:

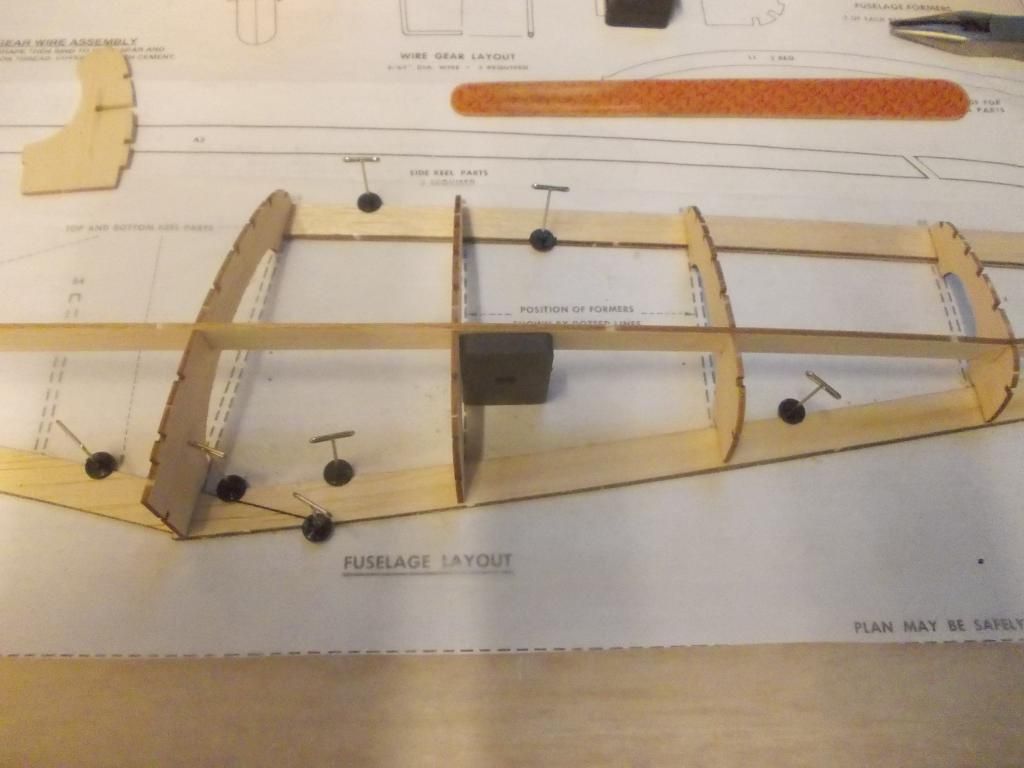

I am building the fuselage on my Guillow's Balsa Board, so I use a couple of magnets to hold the square for me. B0 is the last one going in. I usually work from B9 towards the front. I skip over B4 or any "floating" rib and will install that when the side keel goes in.

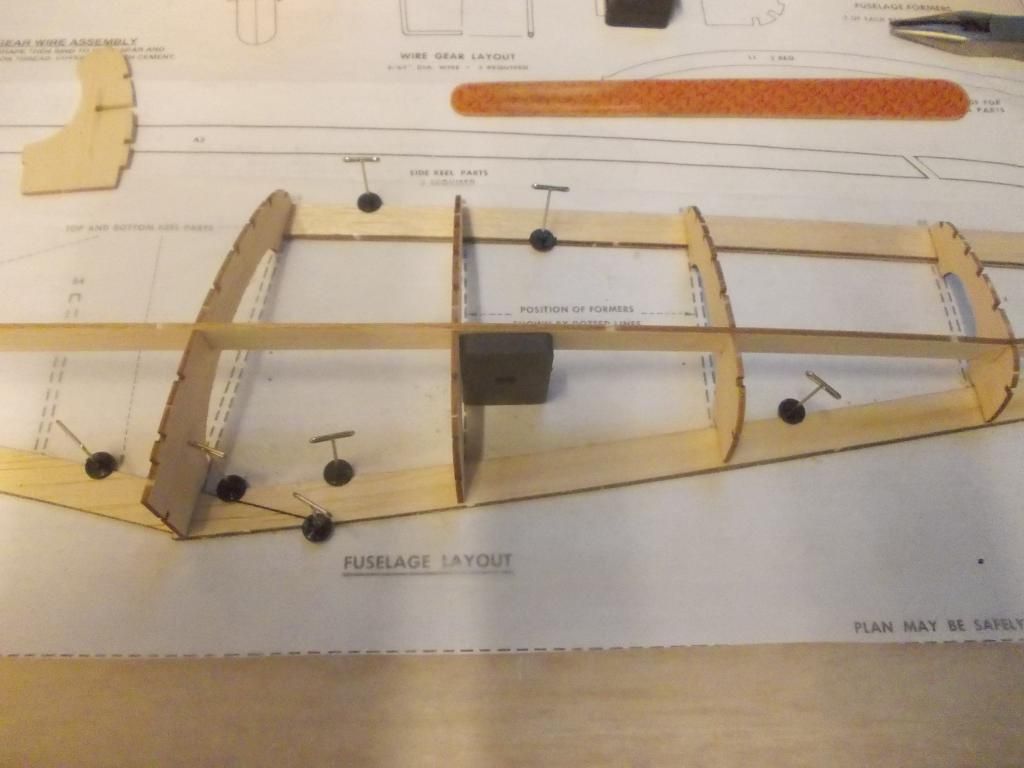

To hold the frames straight as the glue dries I employ the use of a magnet, I also use the boxes the x-acto blades come in when you buy the 15 pack.

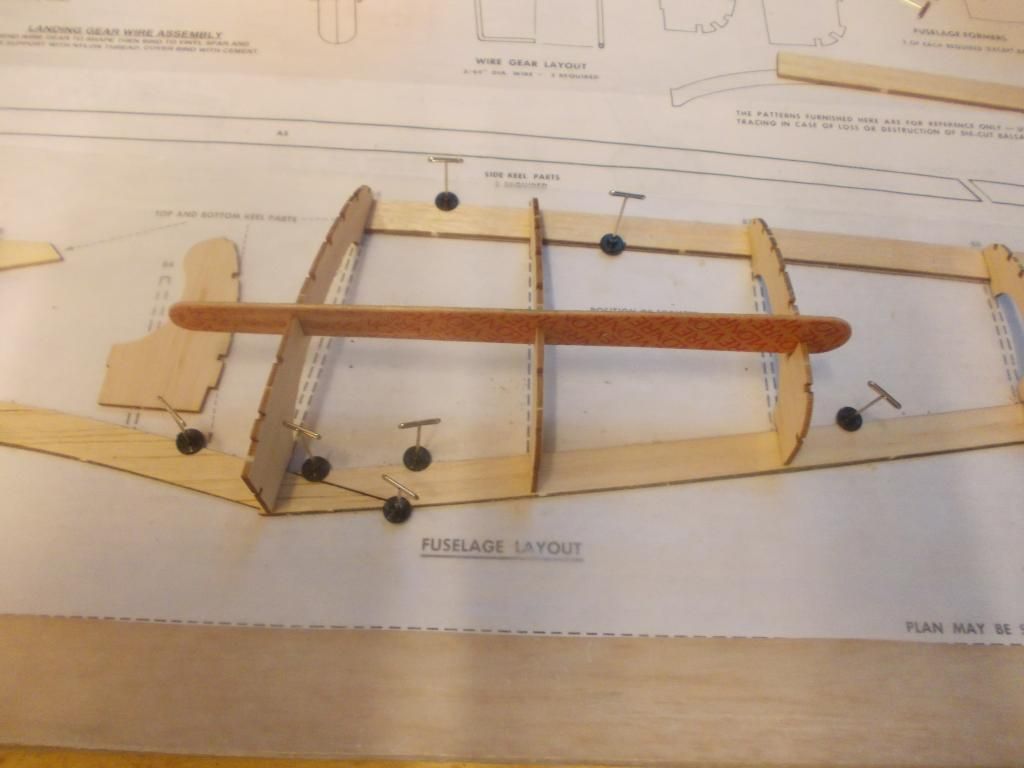

I can also use a couple of "T" pins. I use a pliers to push the pin in close to the frame, then turn the head to support the frame:

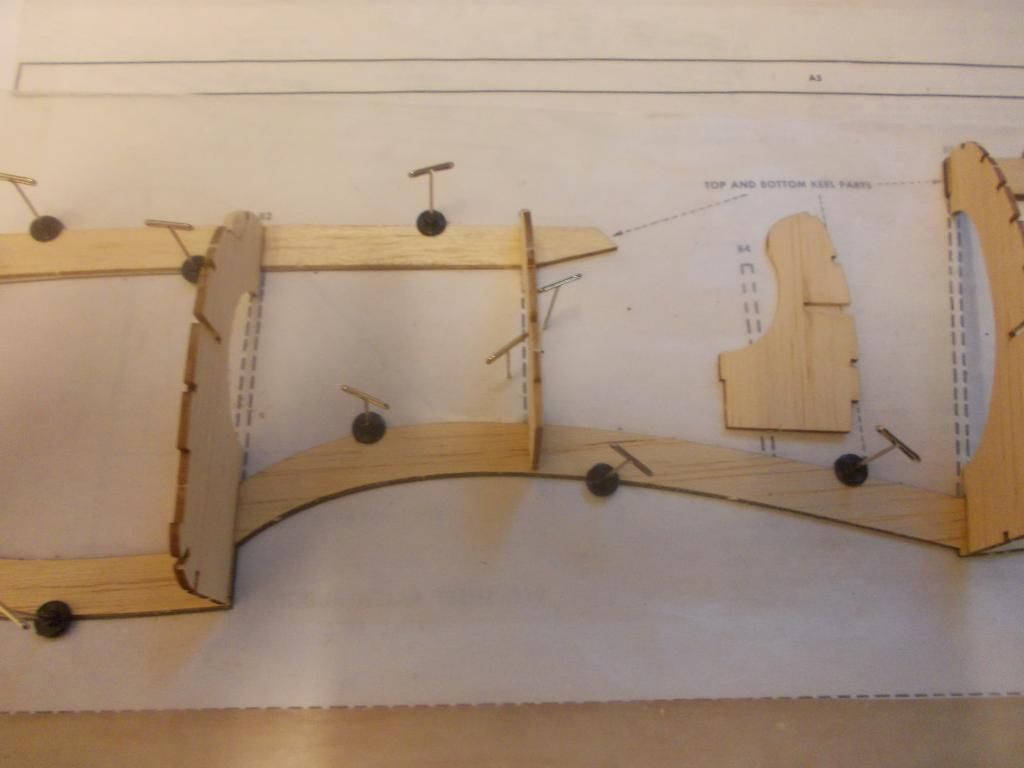

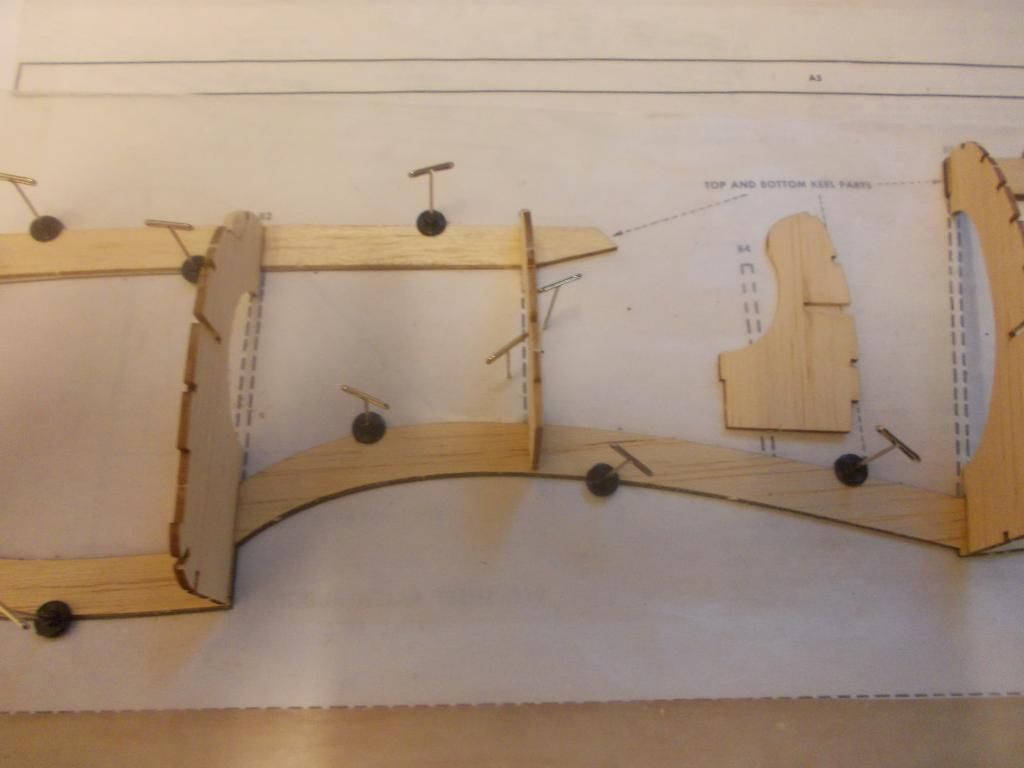

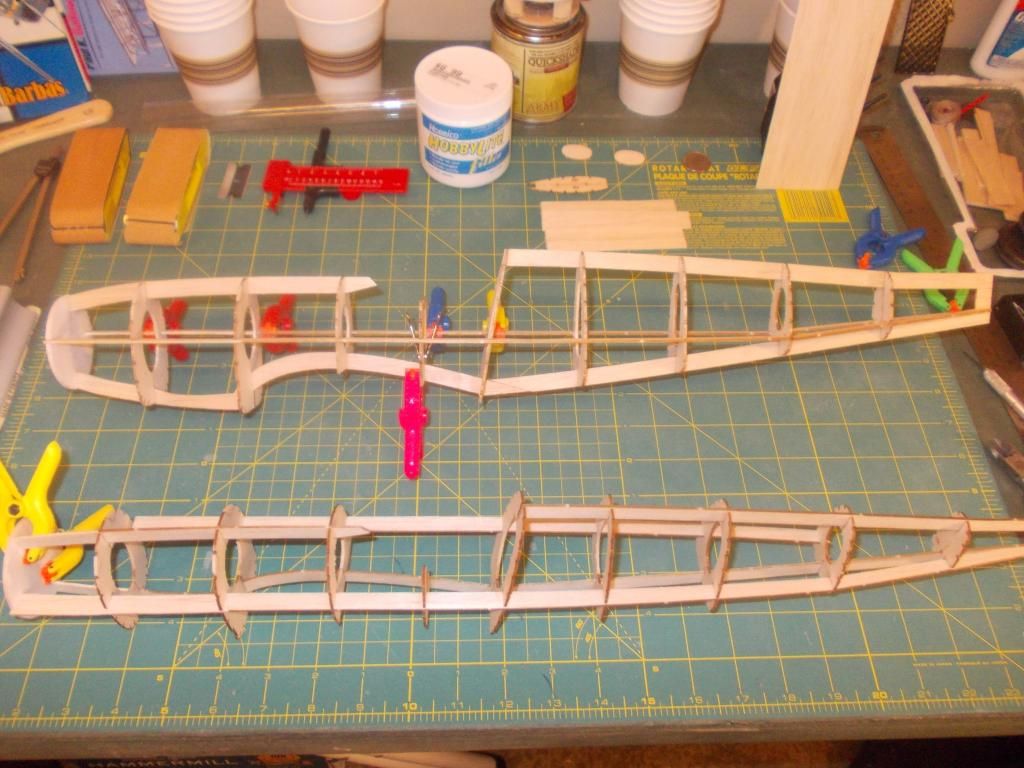

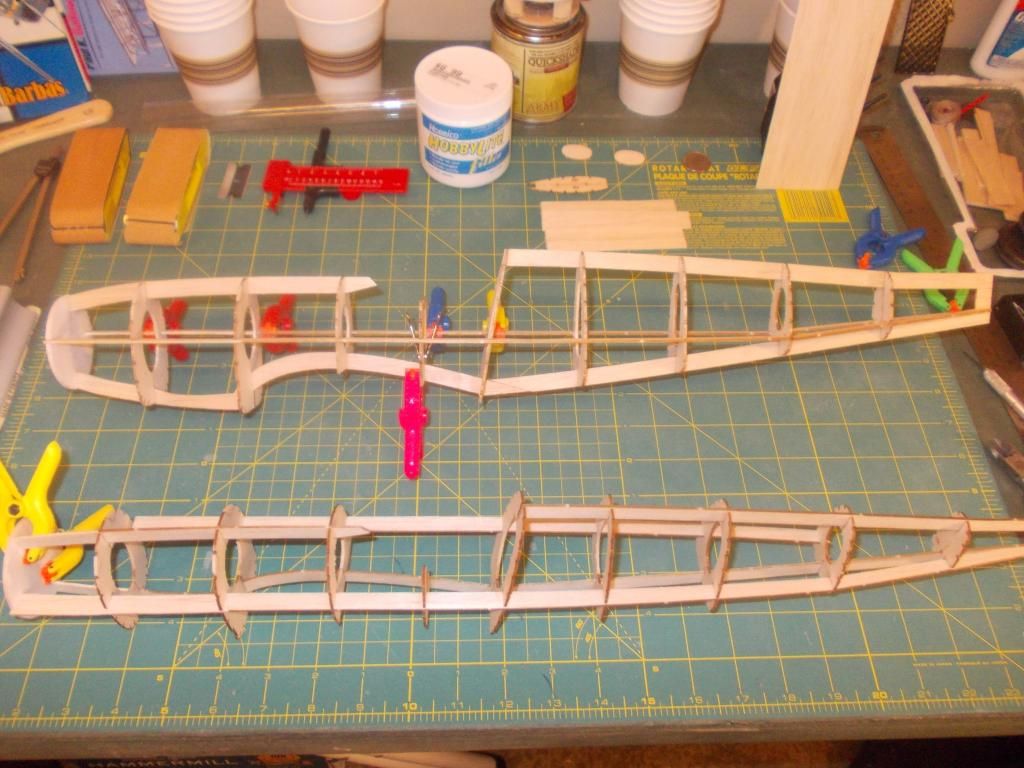

When the half frame is complete I start clamping the other B parts:

Oh... and one more thing...Although laser cut parts are GREAT, I find that fitting in side keels, longrons, and stringers are a tight fit. Even though I sanded the side keels, I will "open" up the notches. For this I use a nail file. It has a course and fine side. It will be a tight fit also.

Carefully sand the notch until it is loose and the side keel will slip right into place. This is a good way to check for alignment as you don't want you longrons to be wavy, also corrects for that angle at B5.

Hope that helps! Mitch

PS: I was planning on building the F-82 also. Just bought the laser cut sheets for the fuselage and canopies from Guillow's parts. But I think I will just build 2 more P-51's.

I use a few different ways to easily check for square. First I use an X-Acto square:

I am building the fuselage on my Guillow's Balsa Board, so I use a couple of magnets to hold the square for me. B0 is the last one going in. I usually work from B9 towards the front. I skip over B4 or any "floating" rib and will install that when the side keel goes in.

To hold the frames straight as the glue dries I employ the use of a magnet, I also use the boxes the x-acto blades come in when you buy the 15 pack.

I can also use a couple of "T" pins. I use a pliers to push the pin in close to the frame, then turn the head to support the frame:

When the half frame is complete I start clamping the other B parts:

Oh... and one more thing...Although laser cut parts are GREAT, I find that fitting in side keels, longrons, and stringers are a tight fit. Even though I sanded the side keels, I will "open" up the notches. For this I use a nail file. It has a course and fine side. It will be a tight fit also.

Carefully sand the notch until it is loose and the side keel will slip right into place. This is a good way to check for alignment as you don't want you longrons to be wavy, also corrects for that angle at B5.

Hope that helps! Mitch

PS: I was planning on building the F-82 also. Just bought the laser cut sheets for the fuselage and canopies from Guillow's parts. But I think I will just build 2 more P-51's.

- Mitch

- Posts: 1347

- Joined: Mon Aug 22, 2011 9:16 pm

- Location: Kent, WA

Re: Double Trouble

Thank You to all you Veterans today. I feel very fortunate that I did not have to serve.

I will be going to PHX for a few days to visit with my Dad. The was in the "Silent Service", U.S. Submarines in WW2.

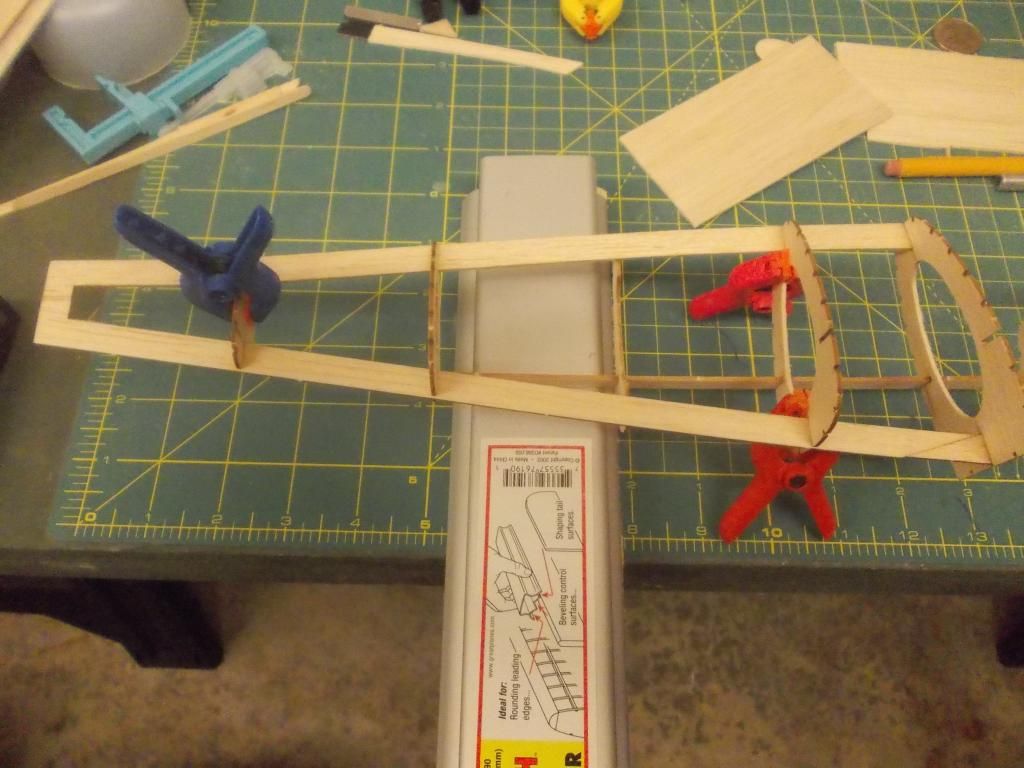

Update on my model, 2 fuselages almost all the frames are in. Need to set the side keel in Second fuselage:

Will finish fuselage skeleton's when I get back home... Mitch

I will be going to PHX for a few days to visit with my Dad. The was in the "Silent Service", U.S. Submarines in WW2.

Update on my model, 2 fuselages almost all the frames are in. Need to set the side keel in Second fuselage:

Will finish fuselage skeleton's when I get back home... Mitch

- Mitch

- Posts: 1347

- Joined: Mon Aug 22, 2011 9:16 pm

- Location: Kent, WA

21 posts

• Page 2 of 2 • 1, 2

Return to General Building Questions

Who is online

Users browsing this forum: No registered users and 19 guests