Trust me it crossed my mind. I just figured it wasn't worth wasting my time on a $13 kit. Plus it was my challenge, and I have a bunch of kits I figured if I could build this one then there was hope for the others, which look in much better condition than this was in. In all fairness the recent kits, even the diecut ones look pretty good. I am sure they have replaced or sharpened the tools since I got this Hellcat.

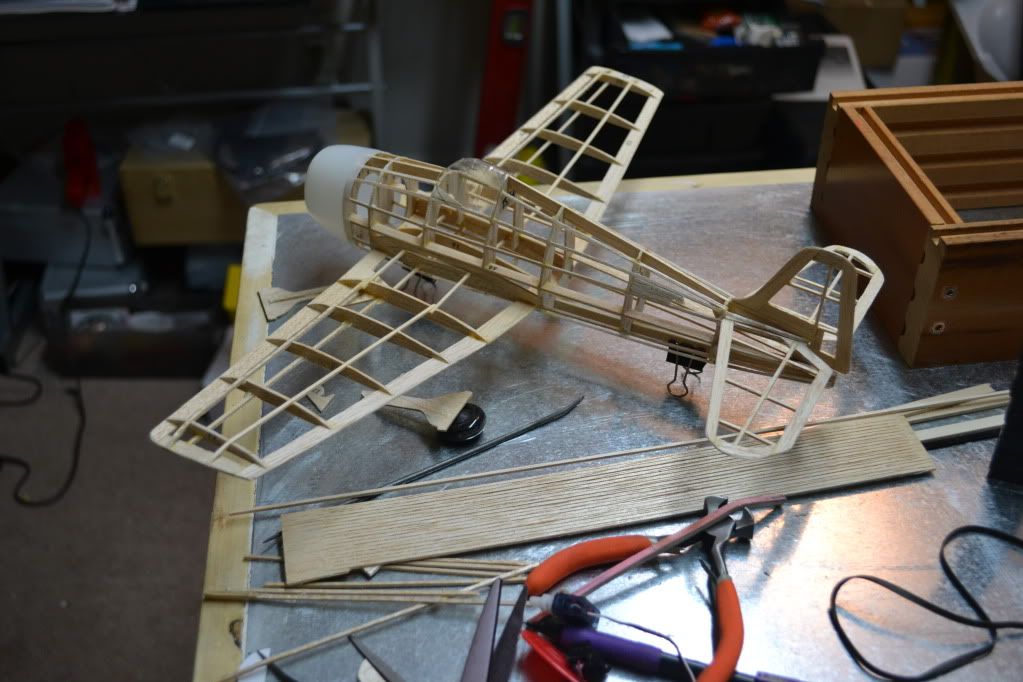

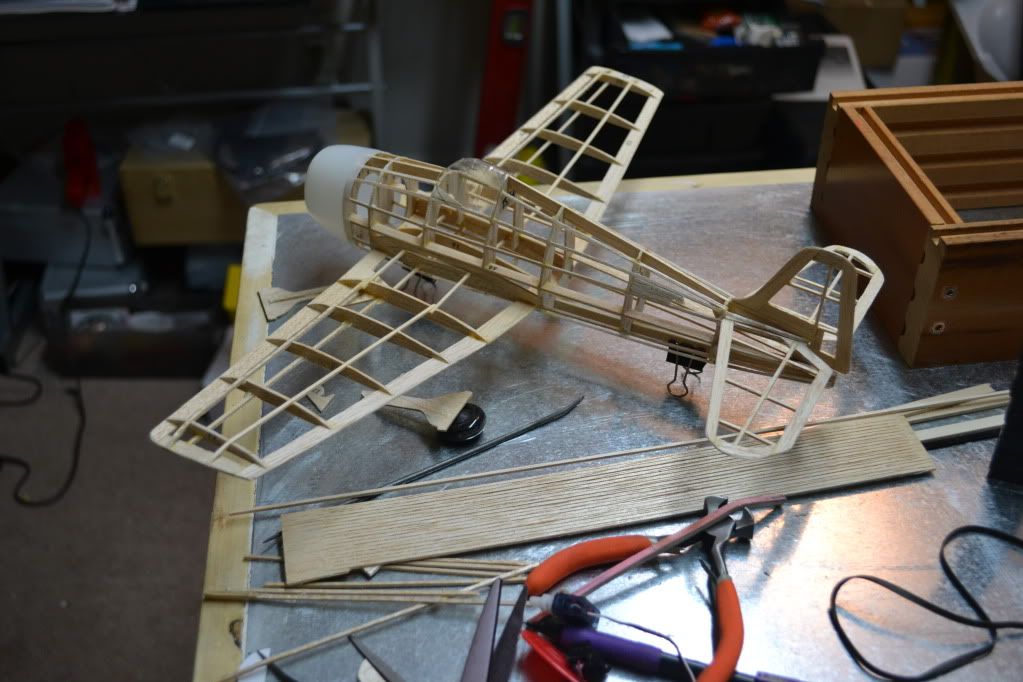

In any event, it probably isn't going to be a flyer, it's 19.5g as it is, but it was a good learning experience. I am tackeling a scratch built Mig-3 now.

Magnets are the only way to build IMHO.

The bench top is galvinzed steel, and it's been great, along with a fuselage jig.