After about fifty years since my last balsa model I’ve been given a Sopwith Camel kit for my birthday!

I am interested in seeing it fly, albeit briefly, but I am a little unsure about my crafting skills so…

1. If I followed the instructions for rubber powered flight, and sanded the balsa components to half their thickness, does that make it more difficult to construct?

Or

2. If I constructed the kit, as for a scale model with full thickness sheet components, would it still fly either, slowly or only a short while?

Thank you… Biplane

Sopwith Camel - help

15 posts

• Page 1 of 1

Re: Sopwith Camel - help

Hi Biplane,

50 years! Too long.

I am not familiar with the Sopwith Camel kit. I have built similar Guillow kits.

To make it a flyer, you can build it just as the instructions say without modification. It will fly. If you have a large front yard, it probably wouldn't leave your yard. If that's all you want,

If you want some "decent" flights. You'll have to shave component thickness, substitute Contest Grade balsa for many of the balsa parts. No paint, cover with Esaki tissue. Big rubber motor. Leave off details.

50 years! Too long.

I am not familiar with the Sopwith Camel kit. I have built similar Guillow kits.

To make it a flyer, you can build it just as the instructions say without modification. It will fly. If you have a large front yard, it probably wouldn't leave your yard. If that's all you want,

If you want some "decent" flights. You'll have to shave component thickness, substitute Contest Grade balsa for many of the balsa parts. No paint, cover with Esaki tissue. Big rubber motor. Leave off details.

- Wildpig

- Posts: 529

- Joined: Thu Jan 26, 2012 9:41 am

Re: Sopwith Camel - help

Welcome... and... I hope you know you are picking a very difficult kit to make fly with a Rubber Motor.

It looks like a wonderful kit. I have it, but not built it yet. I have built all the 400 series as per instructions and they will fly, but just modestly in a school yard. I have built the SE5a and Tripe, but did not have them fly. I am planning on the Nieport next and plan to lighten it up substantially.

My experience with the FAC in the past year has shown me that guys who fly WW1 have planes in the 22 -24 inch ws range. Moreover they are VERY light.

The difficulty (as I see it) with the Camel...

1. Very large = Heavy.

I believe you will have to make modifications. Drop half the ribs in the wing. Drilling holes in the ribs will save more weight than sanding in half.

2. Scale Model = Difficult to trim.

I would add more dihedral, make Vertical Fin 10-15% larger.

3. Radial Engine = Short nose = lots of balancing clay = weight.

Most WW1 planes I see at FAC are Fokker D-7's and SE5a's, because they have a longer nose so the you have more leverage for balancing clay.

A better Guillow model would be the SE5a laser cut... This will also require lightening.

Oh... and another thing, building a biplane is more difficult than a monoplane. I know you have the Camel, and it is wonderful. If I have not scared you off, I would suggest build it as per plans. When you are finished weigh the model. My goal is now .5 grams per square inch of wing loading. My guess is you will be OVER 1 gram per square inch. I believe if you are over .75 grams per square inch the model will not fly. You will have a wonderful display model and can decide how to go from there.

My purpose is to not discourage you. I what you to know what you are getting into.

Mitch

It looks like a wonderful kit. I have it, but not built it yet. I have built all the 400 series as per instructions and they will fly, but just modestly in a school yard. I have built the SE5a and Tripe, but did not have them fly. I am planning on the Nieport next and plan to lighten it up substantially.

My experience with the FAC in the past year has shown me that guys who fly WW1 have planes in the 22 -24 inch ws range. Moreover they are VERY light.

The difficulty (as I see it) with the Camel...

1. Very large = Heavy.

I believe you will have to make modifications. Drop half the ribs in the wing. Drilling holes in the ribs will save more weight than sanding in half.

2. Scale Model = Difficult to trim.

I would add more dihedral, make Vertical Fin 10-15% larger.

3. Radial Engine = Short nose = lots of balancing clay = weight.

Most WW1 planes I see at FAC are Fokker D-7's and SE5a's, because they have a longer nose so the you have more leverage for balancing clay.

A better Guillow model would be the SE5a laser cut... This will also require lightening.

Oh... and another thing, building a biplane is more difficult than a monoplane. I know you have the Camel, and it is wonderful. If I have not scared you off, I would suggest build it as per plans. When you are finished weigh the model. My goal is now .5 grams per square inch of wing loading. My guess is you will be OVER 1 gram per square inch. I believe if you are over .75 grams per square inch the model will not fly. You will have a wonderful display model and can decide how to go from there.

My purpose is to not discourage you. I what you to know what you are getting into.

Mitch

- Mitch

- Posts: 1347

- Joined: Mon Aug 22, 2011 9:16 pm

- Location: Kent, WA

Re: Sopwith Camel - help

i have begun building models again after 30yrs. it starts innocently enough with someone giving you a kit as agift, but the next thing you know , you gotta have more. better flights. constantly improving, more tools and gadgets. And before you know it your hooked again. i remember my first model was a Guillows biplane. I cant remember what model. I was maybe 12. I built it as per plan , and like Mitch said, it flew but not very far. what i did was put a Co2 motor on it, and it did fly for as long as it had pressure. Recently I inquired where to get a Co2 motor at my Hobby store, and they looked at me like i was nuts. I dont know when they stopped making yhem, but i was surprised they didnt anymore. I thoyght it was an excellent cousin of rubber power, and am surprised it never caught on. if anyone knows if they are still obtainable please let me know.

- davidchoate

- Posts: 1263

- Joined: Wed Aug 14, 2013 6:41 am

- Location: PHiladelphia PA

Re: Sopwith Camel - help

Thanks for all your comments, I will try and modify the kit for lightness [but not too extreme, this time]. Some years ago I built [and raced] a Caterham 7 so I have some understanding of the value of shedding weight!

David your pictures of the finished model are a bit intimidating for an [old] beginner!

Probably a silly question but - how do you practically, drill holes in the ribs? Balsa seems very fragile, should you sandwich the component with pieces of wood and drill through? What kind of drill? How much can you remove?

Cheers

David your pictures of the finished model are a bit intimidating for an [old] beginner!

Probably a silly question but - how do you practically, drill holes in the ribs? Balsa seems very fragile, should you sandwich the component with pieces of wood and drill through? What kind of drill? How much can you remove?

Cheers

- Biplane

- Posts: 4

- Joined: Thu Oct 24, 2013 6:46 am

Re: Sopwith Camel - help

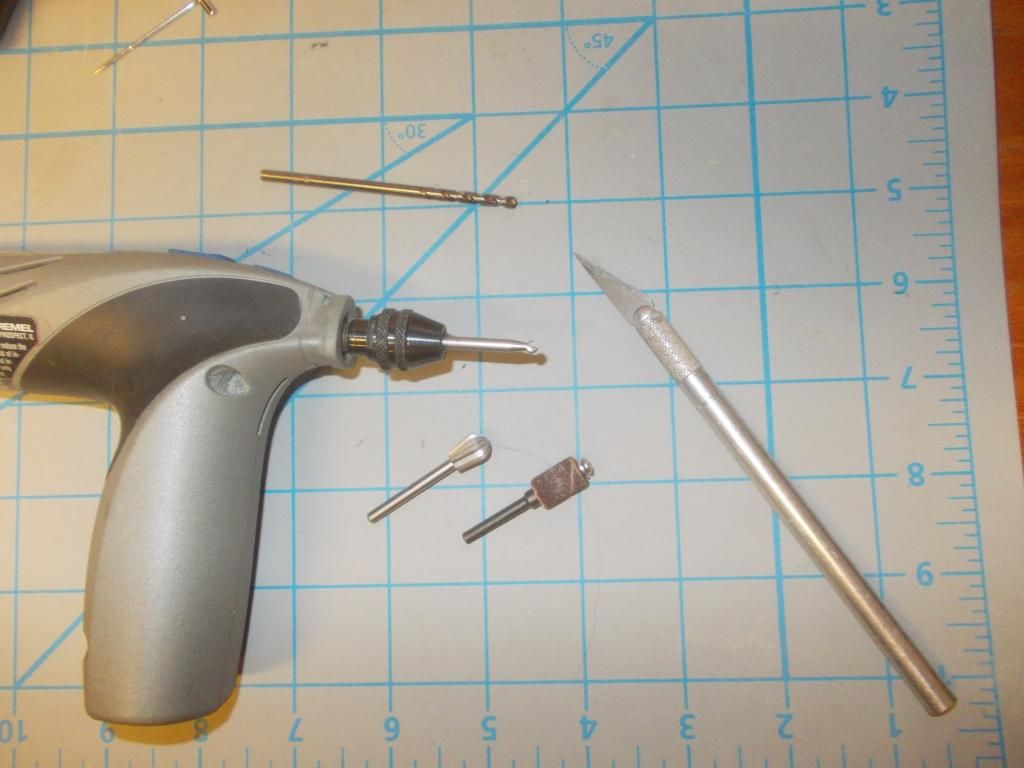

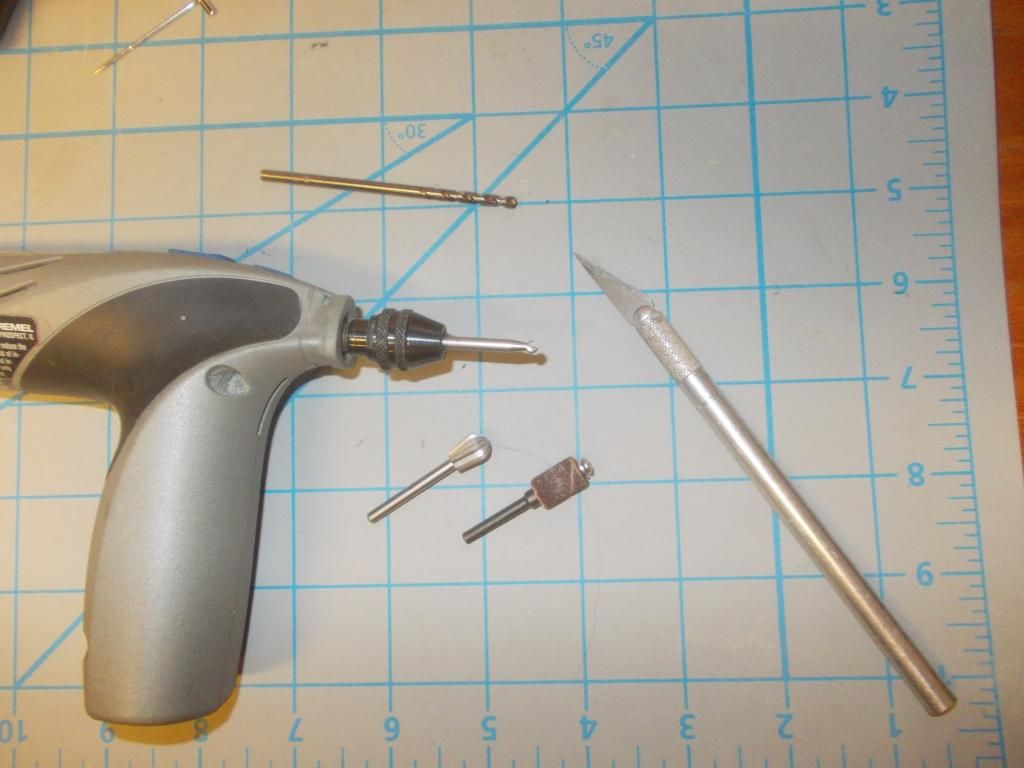

Biplane wrote: "how do you practically, drill holes in the ribs?"

The easiest for me is to cut the holes out with a #11 blade hobby (X-Acto) knife or a rat tail file. Final shaping can be done with sandpaper formed into a cone if you like. Alternatively, you can make a hole saw by sharpening the inside of a brass tube with a tapered reamer. You would need a different diameter tube for each size hole you want to make. You can also buy Forstner bits and chuck them in a hand or power drill.

Lightening holes tend to work best in structural members that have a large surface area and are lightly stressed. Hole locations should be where cross-grain loads are the lowest, near the neutral axis and away from extreme fibers.

The easiest for me is to cut the holes out with a #11 blade hobby (X-Acto) knife or a rat tail file. Final shaping can be done with sandpaper formed into a cone if you like. Alternatively, you can make a hole saw by sharpening the inside of a brass tube with a tapered reamer. You would need a different diameter tube for each size hole you want to make. You can also buy Forstner bits and chuck them in a hand or power drill.

Lightening holes tend to work best in structural members that have a large surface area and are lightly stressed. Hole locations should be where cross-grain loads are the lowest, near the neutral axis and away from extreme fibers.

- David Lewis

- Posts: 289

- Joined: Thu Jun 13, 2013 11:47 am

- Location: Orlando FL

Re: Sopwith Camel - help

i would put all of the ribs together in a soft clamp and drill them together at once to minimize breakage, and give a nice appearance.

- davidchoate

- Posts: 1263

- Joined: Wed Aug 14, 2013 6:41 am

- Location: PHiladelphia PA

Re: Sopwith Camel - help

For hole I use my Dremel tool:

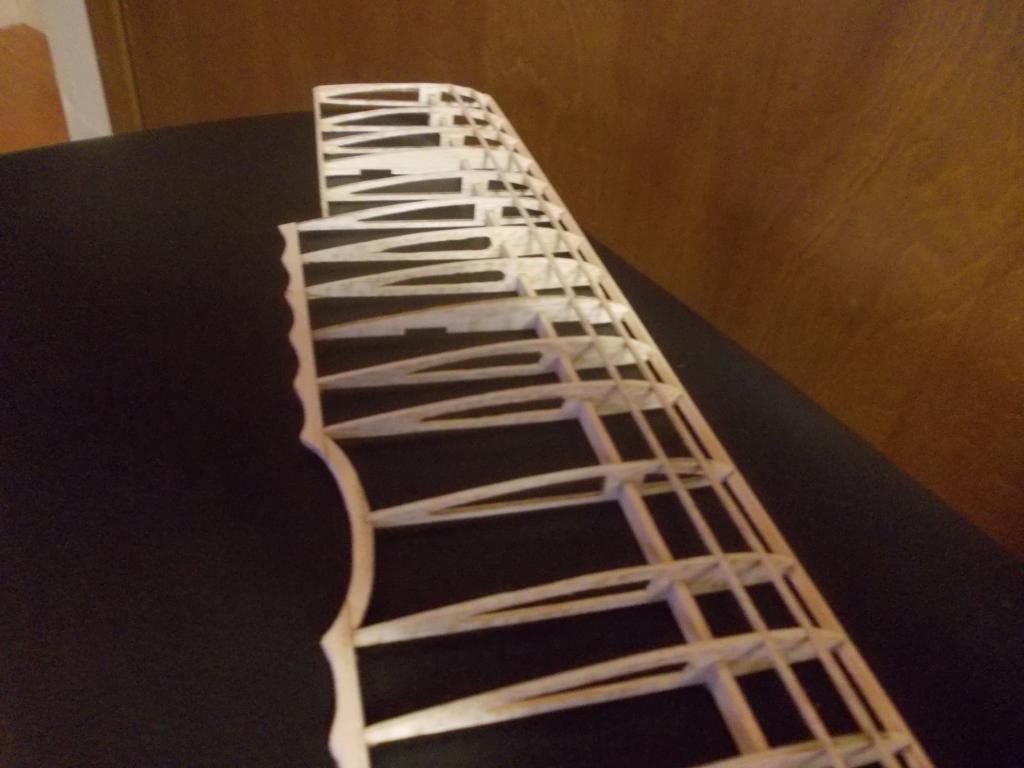

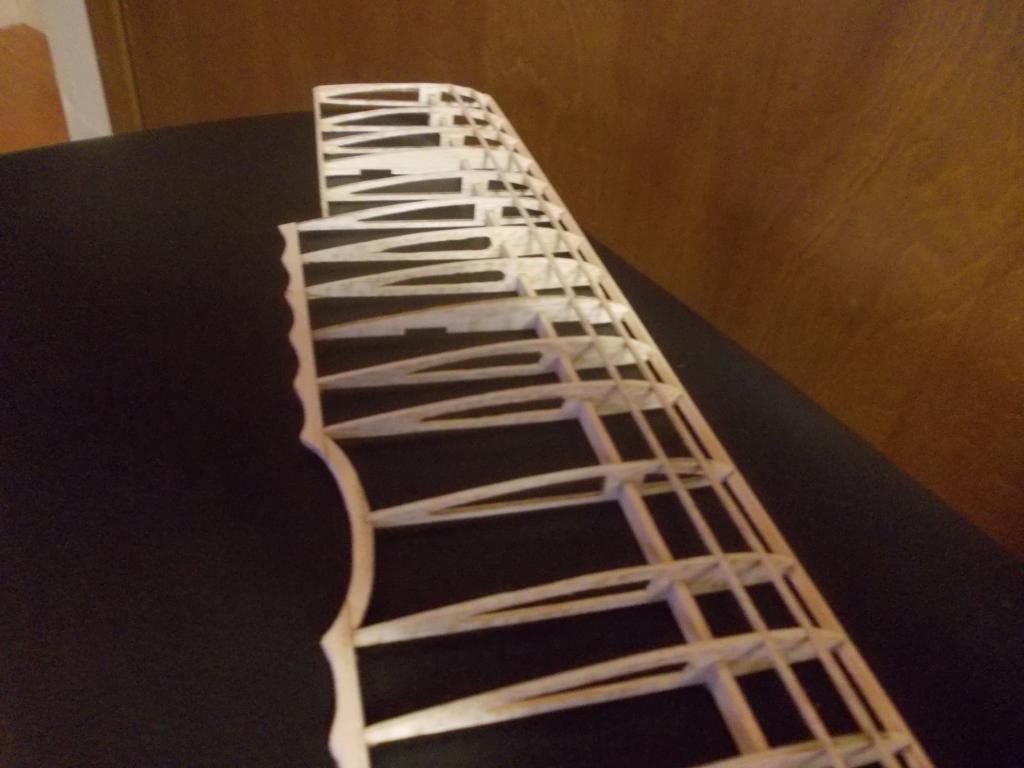

On my latest project, the Edge 540, I cut the hole after the wing was assembled:

That way the stingers were in to give the ribs more strength and I could choose where to drill the hole.

Since the Camel has equal chord ribs you can stack them together and carefully drill a few holes. Of course have some back up wood behind the last rib.

I read from Don Ross' book in Ch 12 about building scale model kits, on how to lighten models. He says this is better to cut holes than using half thickness ribs. I have used 1/32 ribs before, but will use lightening hole from now on.

Mitch

UPDATE: Here is picture of a Fokker D7 wing that I am working on:

The ribs are laser cut, but I added more and cut out the centers to match the laser pieces. Adding more ribs and making movable ailerons is NOT recommended to a Rubber Motor Flying model.

On my latest project, the Edge 540, I cut the hole after the wing was assembled:

That way the stingers were in to give the ribs more strength and I could choose where to drill the hole.

Since the Camel has equal chord ribs you can stack them together and carefully drill a few holes. Of course have some back up wood behind the last rib.

I read from Don Ross' book in Ch 12 about building scale model kits, on how to lighten models. He says this is better to cut holes than using half thickness ribs. I have used 1/32 ribs before, but will use lightening hole from now on.

Mitch

UPDATE: Here is picture of a Fokker D7 wing that I am working on:

The ribs are laser cut, but I added more and cut out the centers to match the laser pieces. Adding more ribs and making movable ailerons is NOT recommended to a Rubber Motor Flying model.

- Mitch

- Posts: 1347

- Joined: Mon Aug 22, 2011 9:16 pm

- Location: Kent, WA

Re: Sopwith Camel - help

Can anyone give me any tips for shaping the leading and trailing edges of the wings?

Thanks in anticipation

Thanks in anticipation

- Biplane

- Posts: 4

- Joined: Thu Oct 24, 2013 6:46 am

Re: Sopwith Camel - help

Short Answer: Sand Paper... as I said in my Toolbox Post... This was AND still is my best tool.

Long Answer: Of course you need to use a block of wood or something to back it up. That is what I used for my early years and it works fine. Of course you want to cut down that square LE first. For that I carefully and slowly use my x-acto knife with a #11 blade. I use this as a draw knife. Carefully and securely hold the wing and start slicing the LE until you are close to the shape you want. Then to the sanding. Start with course grit and end with fine paper.

For the TE, I do NOT touch that with a knife, it is close enough already. I just follow the contour of the ribs and use my small sanding block.

A block of wood works, but as I expanded my toolbox I found nice sanding blocks at my LHS (local hobby shop) If you do not have one near by you can order off the internet. I have some from Great Planes... 5.5 " Easy Touch Hand Sander, 11" Easy Touch Bar Sander. They also make an 11" Easy Touch Contour sander, but I find that of limited use for these small models. That one is for larger RC model with ws of 6 feet or more!

Hope that helps! Mitch

Long Answer: Of course you need to use a block of wood or something to back it up. That is what I used for my early years and it works fine. Of course you want to cut down that square LE first. For that I carefully and slowly use my x-acto knife with a #11 blade. I use this as a draw knife. Carefully and securely hold the wing and start slicing the LE until you are close to the shape you want. Then to the sanding. Start with course grit and end with fine paper.

For the TE, I do NOT touch that with a knife, it is close enough already. I just follow the contour of the ribs and use my small sanding block.

A block of wood works, but as I expanded my toolbox I found nice sanding blocks at my LHS (local hobby shop) If you do not have one near by you can order off the internet. I have some from Great Planes... 5.5 " Easy Touch Hand Sander, 11" Easy Touch Bar Sander. They also make an 11" Easy Touch Contour sander, but I find that of limited use for these small models. That one is for larger RC model with ws of 6 feet or more!

Hope that helps! Mitch

- Mitch

- Posts: 1347

- Joined: Mon Aug 22, 2011 9:16 pm

- Location: Kent, WA

Re: Sopwith Camel - help

One of the things I messed up on my first model was I sanded too much and removed some more material than i should have. balsa is very very soft. I now sand very lightly, stop, look at the LE shape on the plan, look at what i'm doing, sand a little, and repeat. I don't worry about the time it takes.

- davidchoate

- Posts: 1263

- Joined: Wed Aug 14, 2013 6:41 am

- Location: PHiladelphia PA

Re: Sopwith Camel - help

I have a small plane that came with my X-ACTO kit purchased 45+years ago. It works very well on the intial shaping, then I switch to the sanding method. I have blocks that I made from 1-1/2 x 3/4 poplar, cut to about 6" lengths. The blocks each have two sanding grits applied with 3-M spray adhesive. The grits I use are 60,80,100,120,240 and 400. Be aware of the wood grain when carving or planing, go the wrong direction and a large sliver will be the result. Take your time, its worth it.

- wmikedavis

- Posts: 44

- Joined: Sun Nov 15, 2009 9:37 pm

- Location: Seattle, WA

Re: Sopwith Camel - help

William H. Parker Jr. (Bill Parker)

President, Parker Information Resources

http://www.parkerinfo.com/ap.htm bparker@parkerinfo.com

President, Parker Information Resources

http://www.parkerinfo.com/ap.htm bparker@parkerinfo.com

- BillParker

- Posts: 1031

- Joined: Sat Jan 19, 2008 1:21 pm

- Location: Houston, Texas

Re: Sopwith Camel - help

Back again...

The build is going well, with a few problems. Can anyone give any tips for 'stringing' the wings? Any particular techniques for fastening the threads? Glue? Knots? how tight should they be?

Thanks in anticipation.

Ian

The build is going well, with a few problems. Can anyone give any tips for 'stringing' the wings? Any particular techniques for fastening the threads? Glue? Knots? how tight should they be?

Thanks in anticipation.

Ian

- Biplane

- Posts: 4

- Joined: Thu Oct 24, 2013 6:46 am

Re: Sopwith Camel - help

I have never built a biplane, but am about to. But I would say not very tight.I had a problem in the past on my Cub 300 where I installed the wing struts without any kind of tension and a few days later noticed a warped wing. I had to unglue it and sand a tiny bit then unwarp the wing. So I would assume u need to be careful.

- davidchoate

- Posts: 1263

- Joined: Wed Aug 14, 2013 6:41 am

- Location: PHiladelphia PA

15 posts

• Page 1 of 1

Return to General Building Questions

Who is online

Users browsing this forum: No registered users and 38 guests