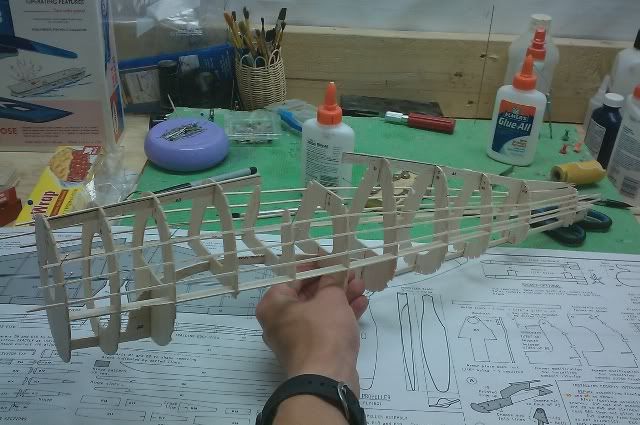

i am pretty disopointed how acurately the parts fit together but..

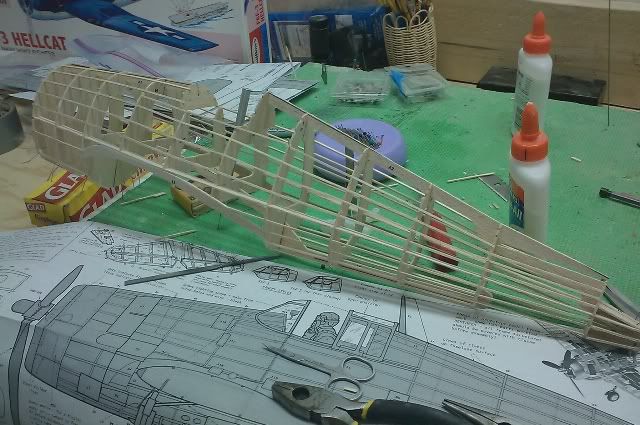

the nose cone was damaged too, which im not too happy about.

guillows really wasnt thinking with how the notche's die cut cuts were positioned. it really just makes everything worse. but i managed to take care of the mods for fully functional display so far and cutting out the notches so its ok.