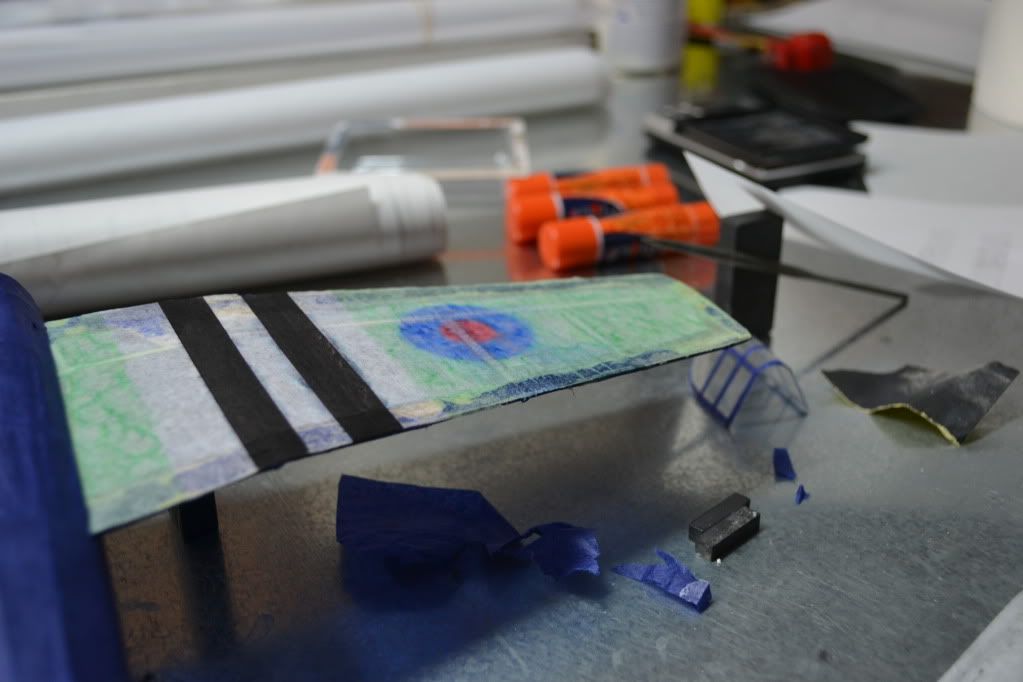

I recovered the lower panel here with Peck Polymer domestic, which doesn’t hold up to water or 50/50 white glue as well as the kit tissue. However, with the dope method and some new tricks I picked up hear and over at SFA it came out nearly wrinkle free.

The printed tissue experiment was a mixed bag. Dope didn’t seem to affect the color nor did alcohol, but water made a mess out of it. Black didn’t seem to be affected by anything, just the color.