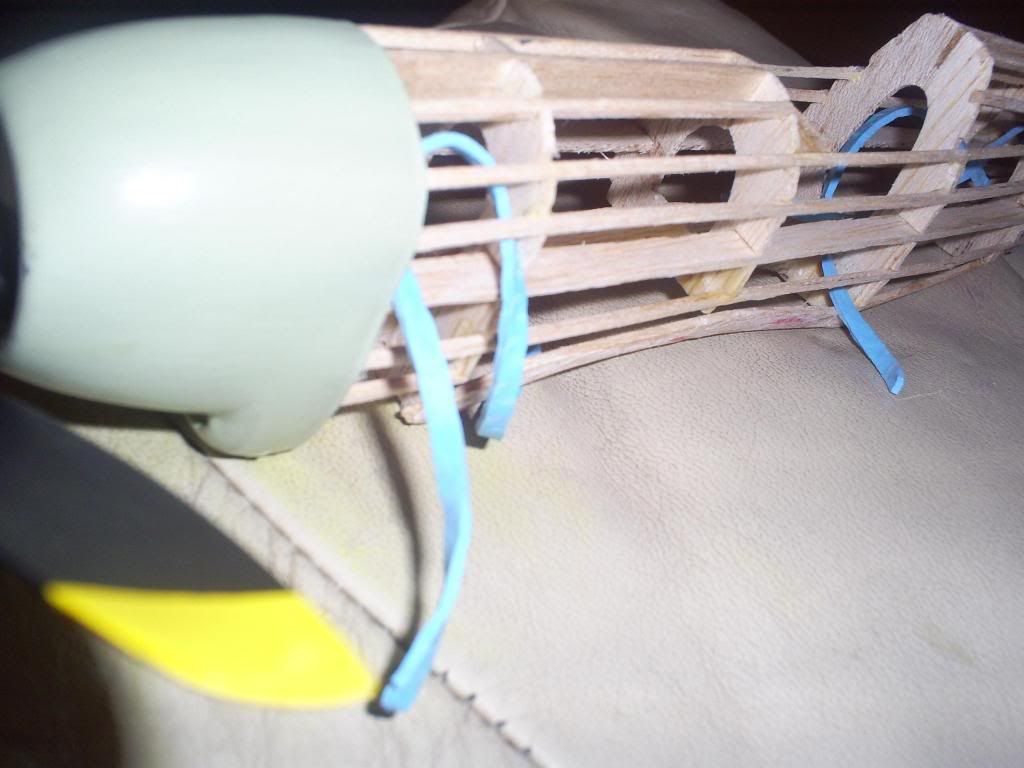

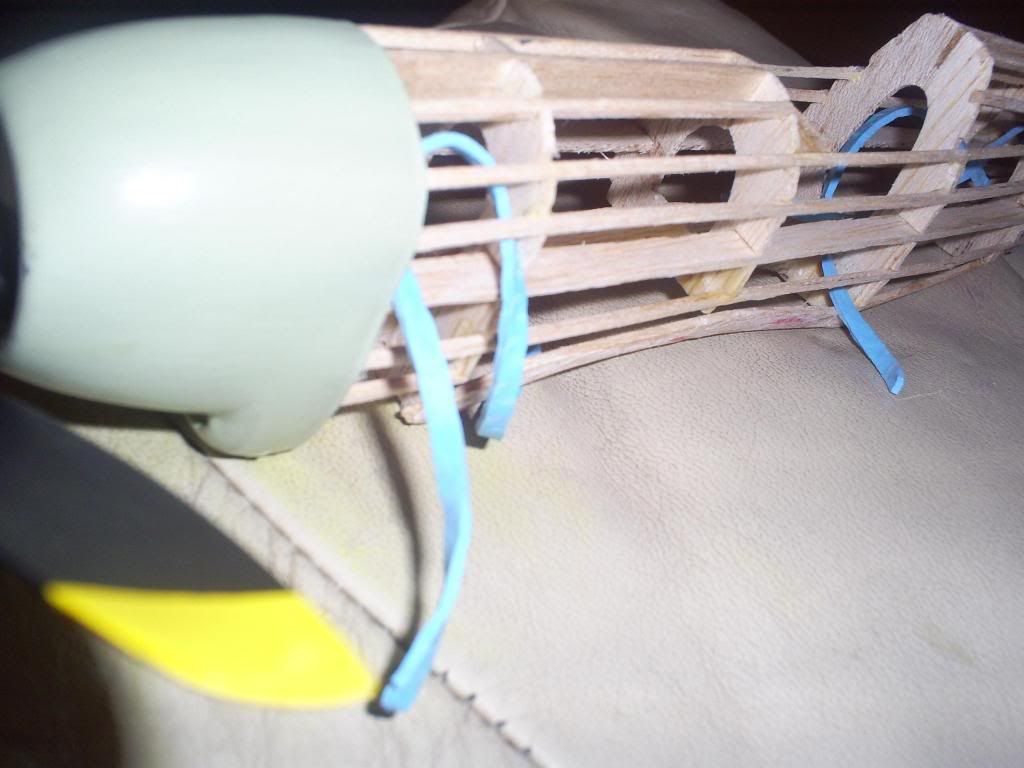

Mitch if you cut the broken ends off, the rubber band looks like a nice tight grape bunch.

There's at least 2 or 3 winds in there.

I would assume most folks do this, but it's probably a good idea to give the entire length a light pull check, looking for any nicks that would cause a failure. I'm not a rubber flyer, but at one time I flew a number of planes with rubber band wing attachment, and learned to test the bands, and replace often also. A few rubber band failure stories I remember are: I had a GWS Beaver slowly lose the ability to climb, while gradually landing whether you wanted to, or not. It was due to the rubber bands stretching and giving out, causing a ridiculous incidence angle. Fortunately only minor damage. Another time was when an AR234 suspended by strings from the ceiling was not there anymore, when I entered the build room. It was on the floor, due to wing attachment rubber bands failing. Fortunately a cabinet just inches below broke it's fall, again with minimal damage as it only had another few feet for the whole mess to tumble to the floor.