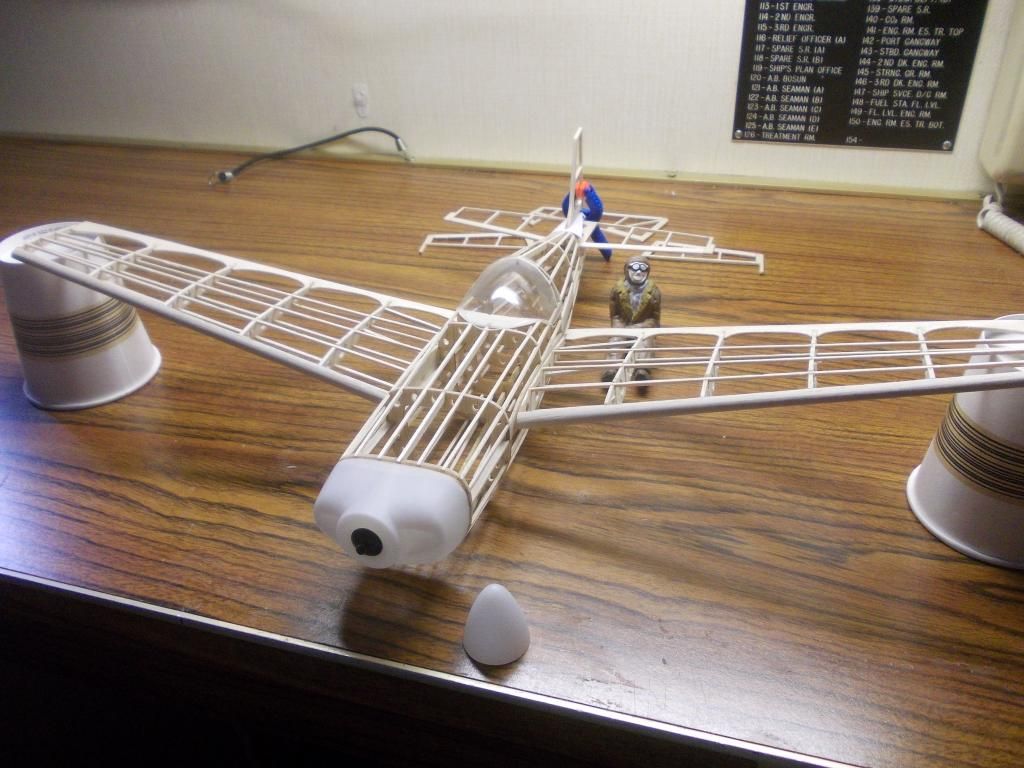

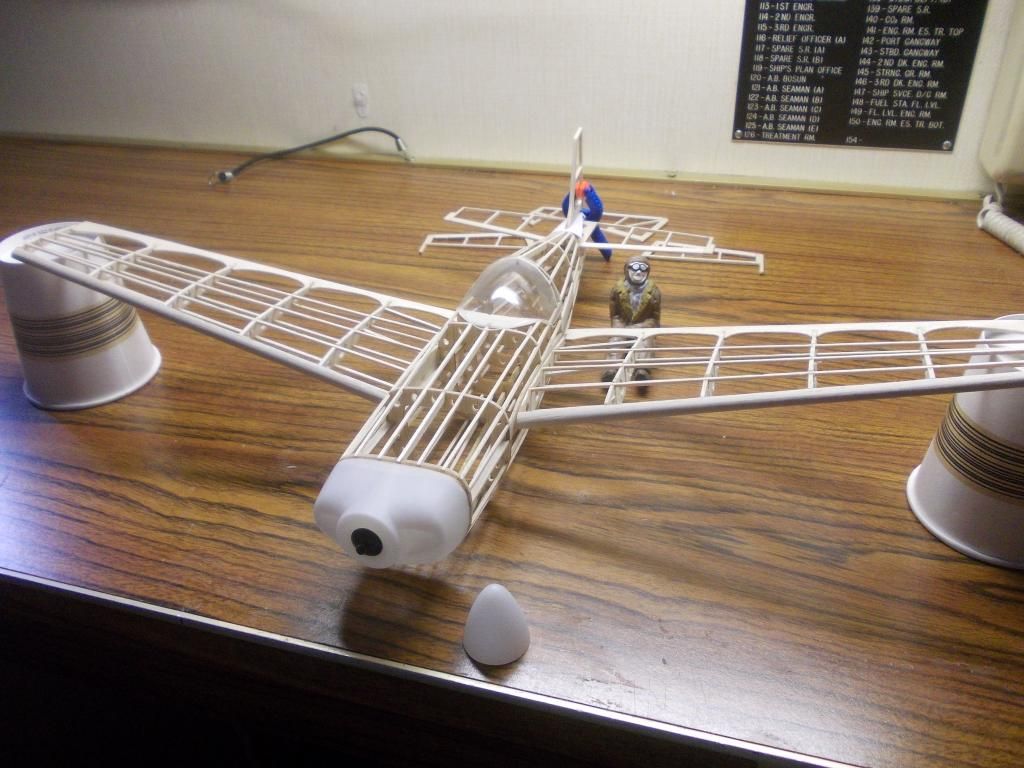

Hey Guys I just posted all my new pics on the other thread Dave started I meant to post it here.

My Skeleton weighs 17.7 g and that was before I drilled it full of holes. I will unpack it and weigh it now to see... I weighed it when our ship was docked in Dutch Harbor. On the trip home I was unable to weigh the model. Everyday I just keep drilling holes!

I started drilling holes and keep going. My scale was not working on the ship as there was too much vibration.

I only reinforced the F0 with some slivers of bamboo. I will need to make the front end adjustable for thrust direction.

I believe if the model is light enough it will have soft landings, not hard impacts! With that small wing weight is critical for wing loading!

Mitch

UPDATE: My skeleton now weighs 16.6 g I was able to remove over 1 g of wood. I plan to start covering tomorrow!

(16.6 g is JUST the wood, NO cowling or CANOPY or gear. The finished model will gain a lot more weight!)