I still do not consider myself an expert, but I realize (and hope) there are newcomers here. I have been learning quite a bit in the last year and thought I would pass to you what I have learned.

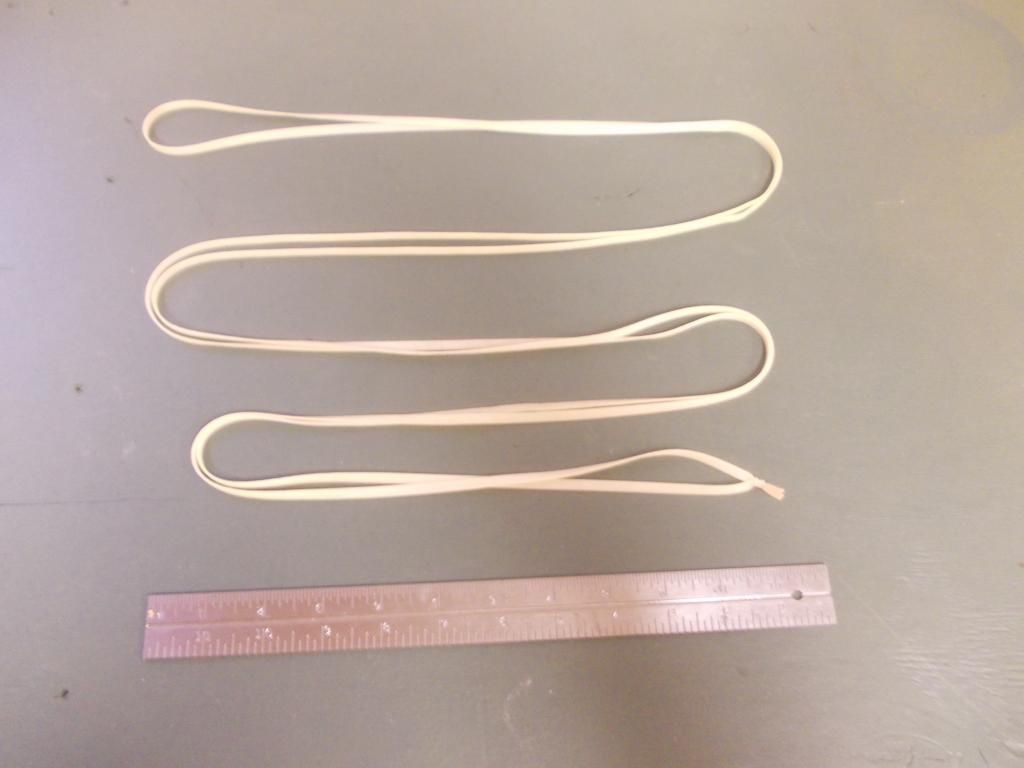

Braiding Rubber Motors - Although I have achieved a few brief flights in my Local Schoolyard with standard Guillow Rubber Motors. I have learned for longer and better flights one must use tan rubber, at greater lengths and loops. The common sizes I have found are 1/8 and 3/16. I would use 1/8 for 500 series type models, and 3/16 for 400 series.

Lets get to the braiding. First choose your rubber motor size. You can determine how much by length or weight. I am still going by length.

1. Here I am starting with 60 inches of 3/16 rubber. I plan to make 2 loops. Tie a knot at the ends. Wet the rubber (in your mouth) and tie 1 overhand knot. Then tie another overhand knot over that and slide it down to the end. If there is a lot of loose ends left, trim them off.

2. You will need some small rubber bands. Dental Bands work very well. Fold the rubber to make the loops you want and secure the end that goes to the peg with the dental band.

3. Slip this secured opening over a post of some sort, in your workshop:

4. Take one loop and wind it backwards until it has a nice curl to it but no knots.

5. Set that aside (I hung it on the banister) and do the same with the other loop.

6. Now put them together and wind them forward:

7. Voila!: (that's about all the French I know) it means "There it is!"

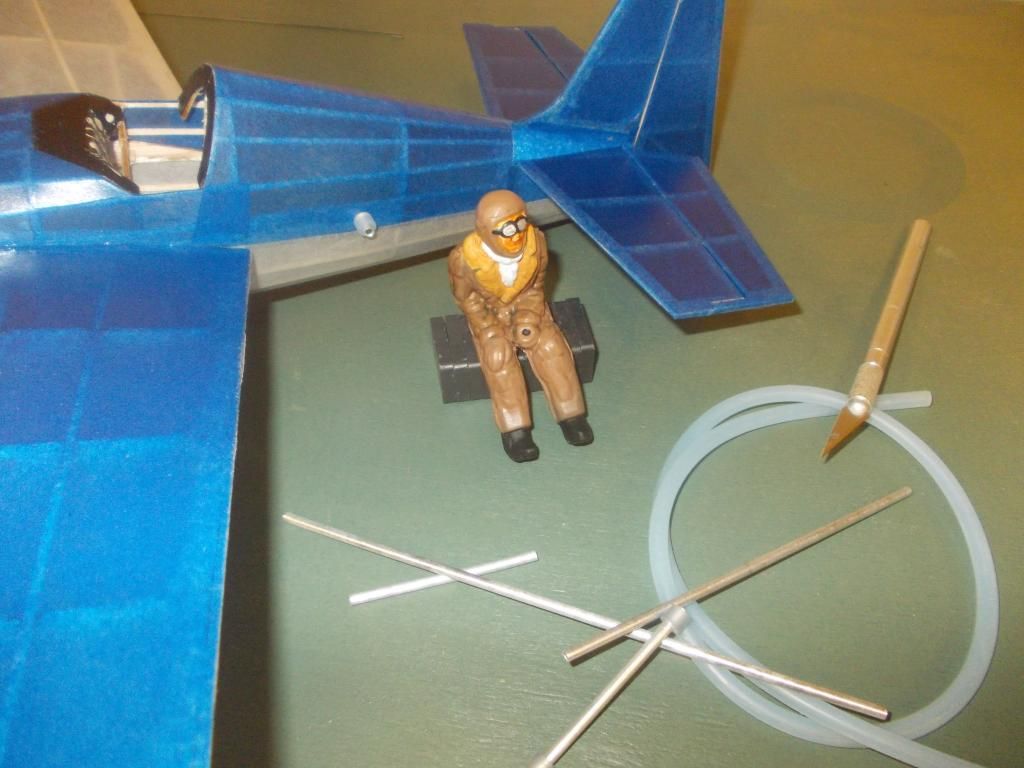

8. I like to use a crocket hook on the front end. I have 2 different sizes:

9. Secure the crocket hook with another dental band to the front end:

10.Don't forget to lube you motor before you use it. I am now using Dow Corning 33, it is a paste:

So there you have it. That's how the PRO's do it and now you can to!

Mitch