BF 109 build..just keeps giving

13 posts

• Page 1 of 1

BF 109 build..just keeps giving

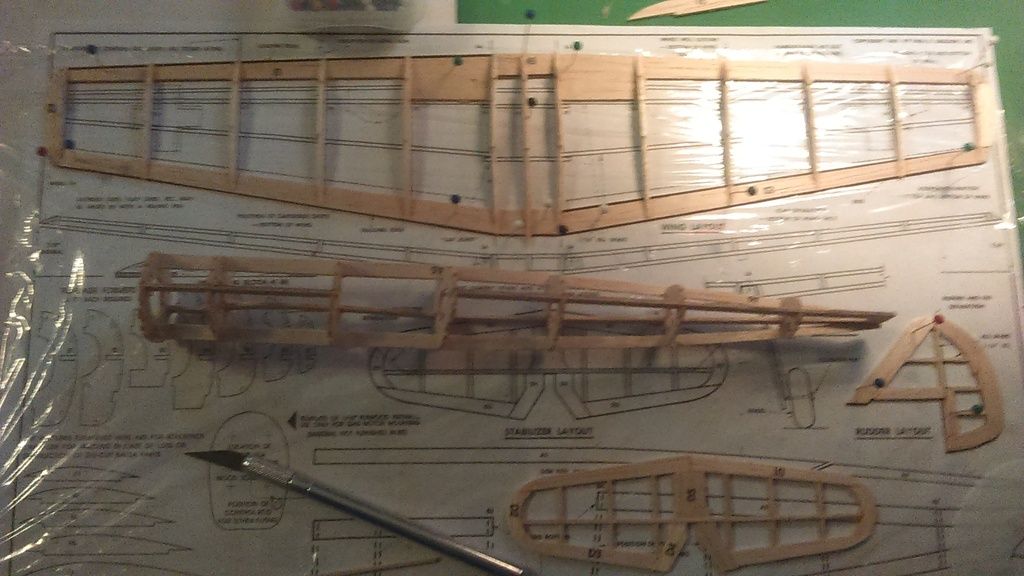

Got a BF 109 build in progress. Pics will be posted as soon as I figure it out. It is not laser cut,but it has been a pain in the butt so far. It started with my "C" sheets being cracked many times with the grain. Guillows kindly replaced for free..thanks! Wing ribs I pretty much had to cut em all out and make every notch by hand. I think I just scored a iffy kit, but undaunted I shall overcome. So it was only going to be a hand built canopy build I was going to post..but...after 4 hours of framework my 3 year old reached up on the desk and grabbed it. So I will include the new canopy build also,but this time I am going to assume anybody that copies it doesnt have access to a supply like mine. We will call it.."Canopy on the cheap".All of my props are spoken for so I havent decided yet what to do there... Pics to come

- NcGunny

- Posts: 203

- Joined: Fri Apr 24, 2015 5:48 pm

- Location: New York

Re: BF 109 build..just keeps giving

Is this the 400 or 500 model. For the 400 I would drop half the wing ribs. The 400 109 go with the extended wing and use even number ribs, the 500 109 build as per plans.

- Mitch

- Posts: 1347

- Joined: Mon Aug 22, 2011 9:16 pm

- Location: Kent, WA

Re: BF 109 build..just keeps giving

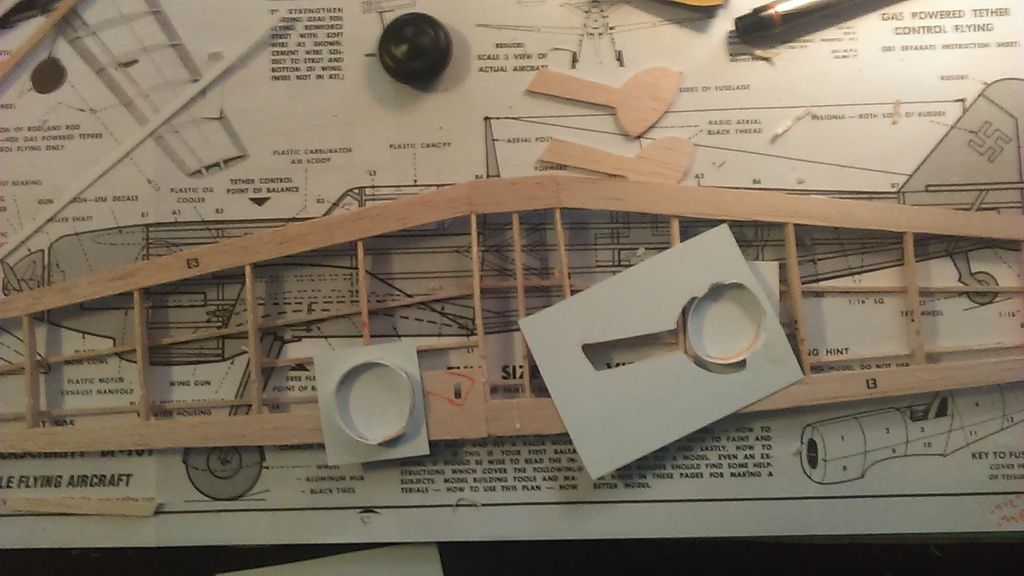

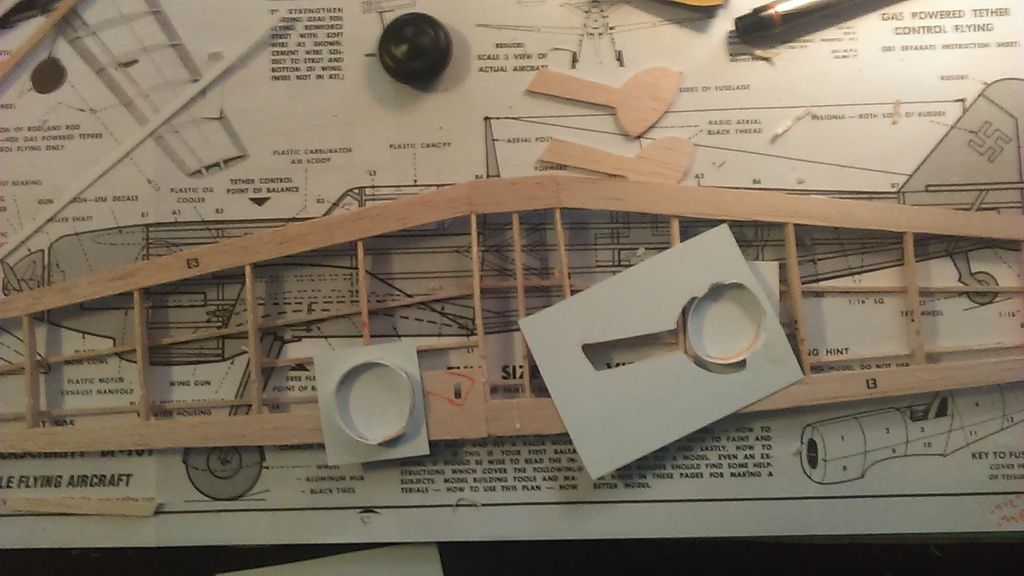

I decided last night to make the landing gear openings in the wings. I traced out a simple outline on .50 cent for sale sign from the Dollar Store. The piece of signs will become the top side of the opening to make it crisp and flat. The bottom of the opening will be a tracing of the wheel pant onto balsa stock. I will show a pic of forming the walls of the landing gear opening,I am not sure that the wing is to scale in depth to actually be able to close up and encase it.If not I will change my landing gear build slightly so that they wont fold and pivot. I just cant see making openings and having a plain stick as a landing gear.

- NcGunny

- Posts: 203

- Joined: Fri Apr 24, 2015 5:48 pm

- Location: New York

Re: BF 109 build..just keeps giving

The compartment where the retracted wheel and strut are stowed is called the "wheel well." The panels attached to the strut or hinged to the wing are the "landing gear doors."

Traditionally, the ceiling of the wheel well is just left as open structure in order to keep the build simple and quick. And since the wheel well walls don't carry any load, they are made out of a light material that is easy to work, such as paper.

The challenge is the wheel well interrupts the lower spar or leading edge right where stress is the highest. Sometimes you can omit the lower spar entirely and the wing will still be strong enough, especially if you use 5-minute epoxy at the dihedral breaks. Alternatively you can relocate the lower spar to miss the wheel opening, keeping in mind the closer the spar is to the maximum thickness of the airfoil, the stronger the wing is going to be, and that spars must carry all the way through the wing center section in order to add bending strength.

What you also want to avoid is scalloping the wing leading edge. That will create a big stress concentration.

Traditionally, the ceiling of the wheel well is just left as open structure in order to keep the build simple and quick. And since the wheel well walls don't carry any load, they are made out of a light material that is easy to work, such as paper.

The challenge is the wheel well interrupts the lower spar or leading edge right where stress is the highest. Sometimes you can omit the lower spar entirely and the wing will still be strong enough, especially if you use 5-minute epoxy at the dihedral breaks. Alternatively you can relocate the lower spar to miss the wheel opening, keeping in mind the closer the spar is to the maximum thickness of the airfoil, the stronger the wing is going to be, and that spars must carry all the way through the wing center section in order to add bending strength.

What you also want to avoid is scalloping the wing leading edge. That will create a big stress concentration.

Last edited by David Lewis on Wed Jun 03, 2015 8:14 am, edited 4 times in total.

- David Lewis

- Posts: 289

- Joined: Thu Jun 13, 2013 11:47 am

- Location: Orlando FL

Re: BF 109 build..just keeps giving

Thxs Dave! So...the stock 2 piece tire rim combo is out of scale for this kit, tire is .412" & wing is .348" at its highest point.Even if i cut off the center hub of a tire and made it flat to simulate a drum brake it would still be .385". I guess the wheel wells become just for look,unless i can find a replacement in my junk pile.

- NcGunny

- Posts: 203

- Joined: Fri Apr 24, 2015 5:48 pm

- Location: New York

Re: BF 109 build..just keeps giving

It's a lot of work but I make my wheels from scratch out of balsa. That way the wheels are to scale:

viewtopic.php?f=2&t=2697

The designer for Vintage Model Co. (UK) laser cuts custom balsa wheels to scale for each kit.

viewtopic.php?f=2&t=2697

The designer for Vintage Model Co. (UK) laser cuts custom balsa wheels to scale for each kit.

You do not have the required permissions to view the files attached to this post.

Last edited by David Lewis on Tue Jun 02, 2015 1:07 pm, edited 1 time in total.

- David Lewis

- Posts: 289

- Joined: Thu Jun 13, 2013 11:47 am

- Location: Orlando FL

Re: BF 109 build..just keeps giving

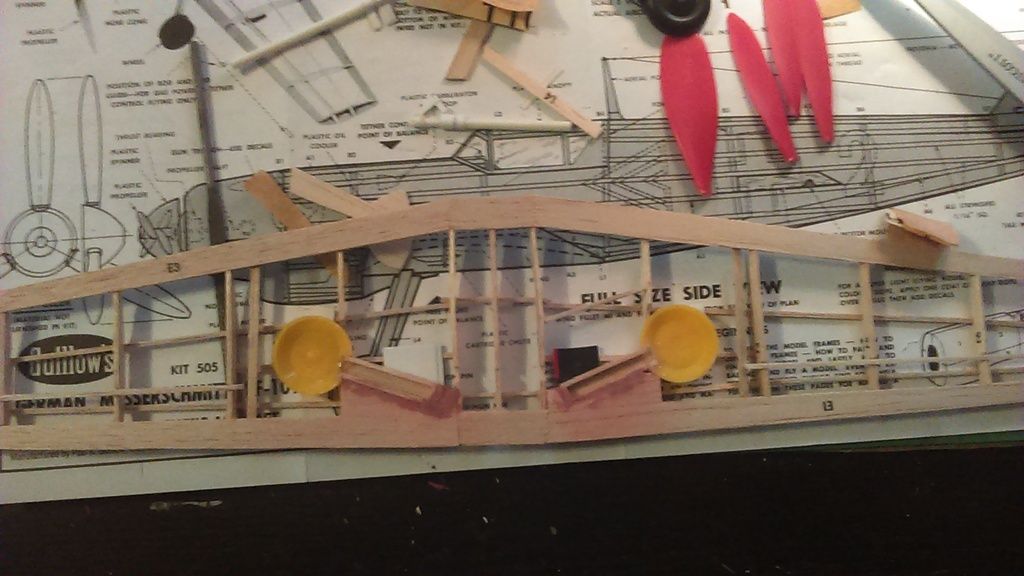

Here is 1 side kinda roughed into shape..not trimmed at all and the landing strut isnt boxed in yet. I had to add cross bracing between ribs F2 and F3. And it looks like a brace on the bottom side also will be needed.. it had occured to me that a thin wall piece of pvc pipe could be used also to box in the wheel section itself

- NcGunny

- Posts: 203

- Joined: Fri Apr 24, 2015 5:48 pm

- Location: New York

Re: BF 109 build..just keeps giving

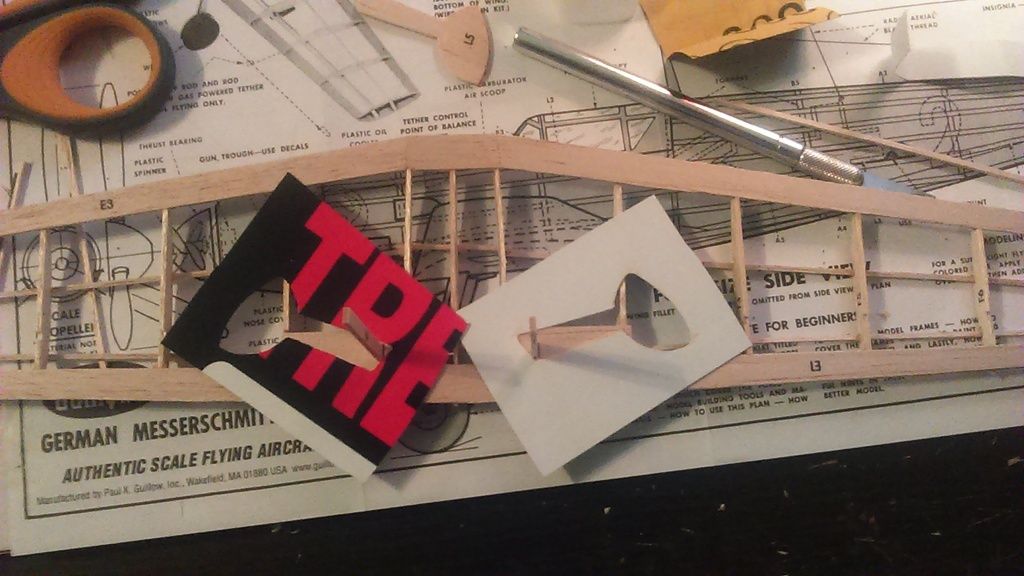

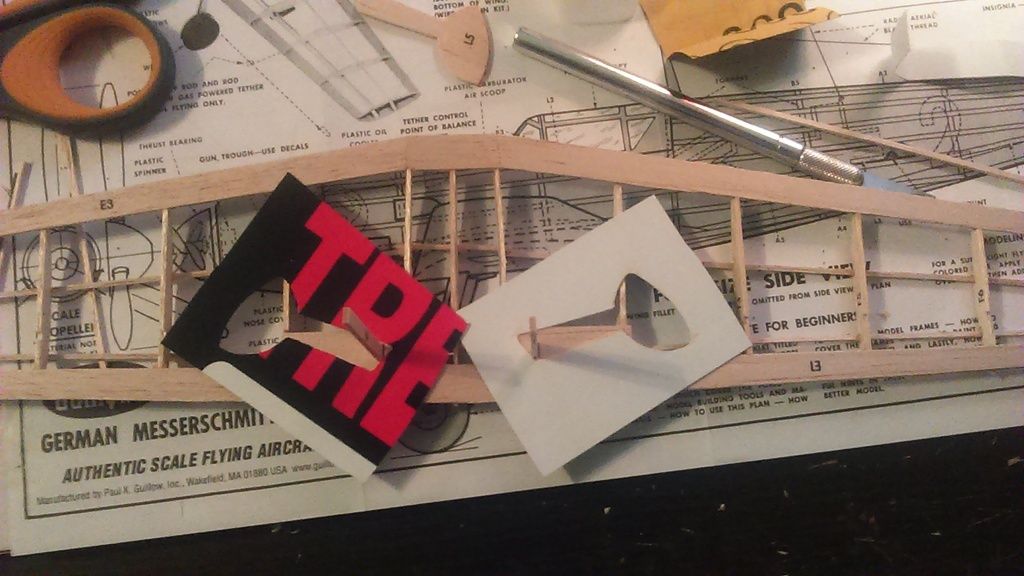

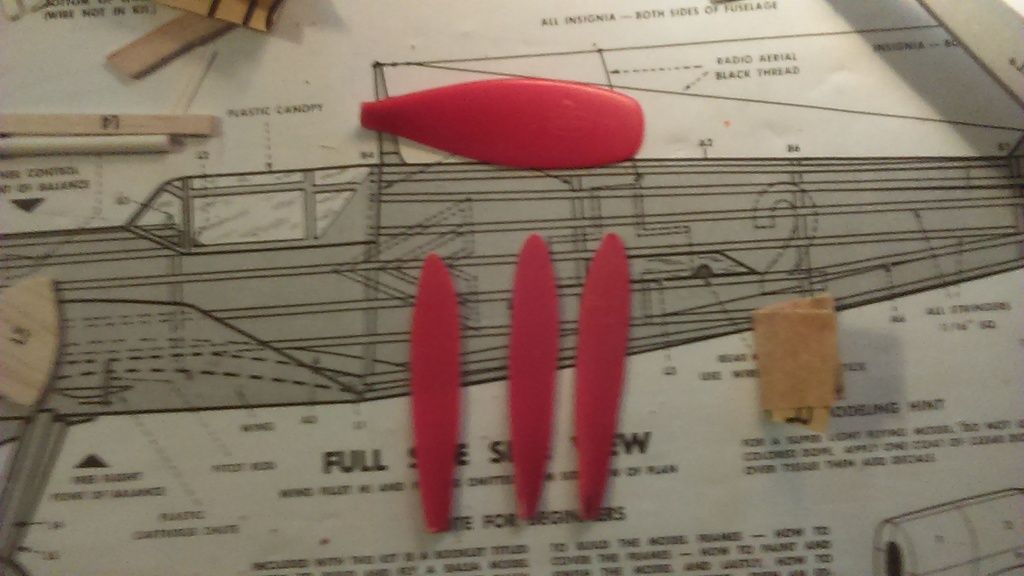

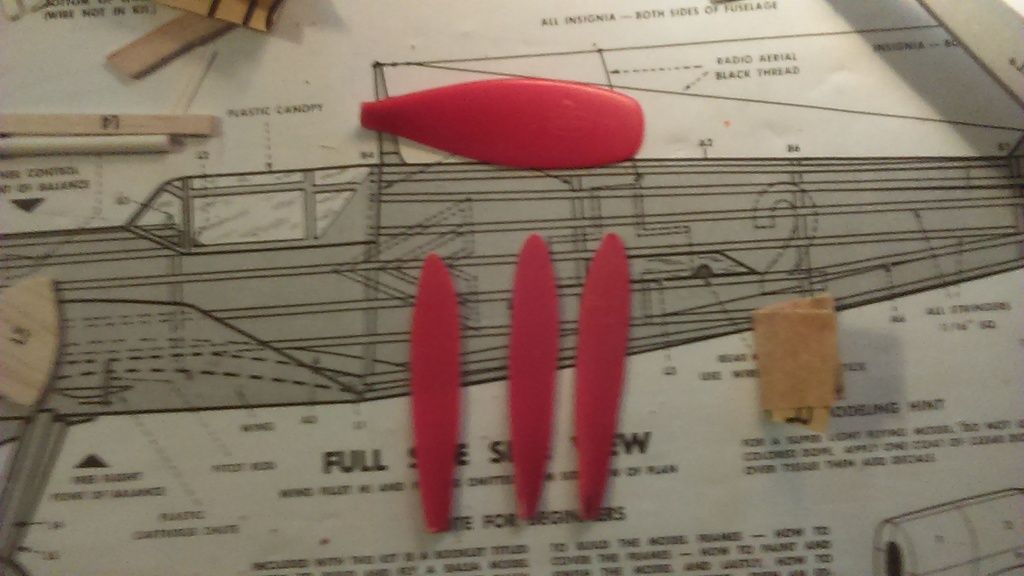

I just did a whole post and lost it all....here we go again.

I decided to see if I could make a acceptable sub for props. I had 3 spare Guillows spinners collecting dust. There is a difference in plastic hardness with these. My suggestion is to score your outline with a xacto first then use a sprue cutter to get your rough shape. If when finished they arent right I will spring for some bought ones.

I decided to see if I could make a acceptable sub for props. I had 3 spare Guillows spinners collecting dust. There is a difference in plastic hardness with these. My suggestion is to score your outline with a xacto first then use a sprue cutter to get your rough shape. If when finished they arent right I will spring for some bought ones.

- NcGunny

- Posts: 203

- Joined: Fri Apr 24, 2015 5:48 pm

- Location: New York

- NcGunny

- Posts: 203

- Joined: Fri Apr 24, 2015 5:48 pm

- Location: New York

Re: BF 109 build..just keeps giving

I decided to mess with the landing gears. 2 pieces of styrene from the sprue tree have kindly donated to the cause. Hard to see the hydraulic between the trailing arm,but is has been sanded smaller for detail and I have a wire built for the hydraulic lines. Not yet cut to length but hopefully they will turn out.

- NcGunny

- Posts: 203

- Joined: Fri Apr 24, 2015 5:48 pm

- Location: New York

Re: BF 109 build..just keeps giving

For strength at minimum weight, Tom Arnold used carbon fiber thread to reinforce a wing spar on his He 219 Uhu in the engine nacelle area so the rubber motor could go through.

- Chris A.

- Posts: 92

- Joined: Tue Apr 01, 2014 10:50 am

Re: BF 109 build..just keeps giving

Update to build..I had been taking pics as i went along to post all at once. Had them stored on a SD card in my phone and as luck would have it..my SD card had a failure and bit the dust. On a even lower note we came home from the store today and I saw little paper crumbs through the livingroom. Cat vs Bf 109...I literally was only able to salvage the props,wheels, wheel wells I made. First time she has ever bothered with any kit of any type. And the BF 109 still keeps giving because chips of balsa are now embeded in the carpet.

- NcGunny

- Posts: 203

- Joined: Fri Apr 24, 2015 5:48 pm

- Location: New York

13 posts

• Page 1 of 1

Return to General Building Questions

Who is online

Users browsing this forum: No registered users and 28 guests