I built one of these on rubber power in 1972 when I was 12 and it didn't fly like a fighter.

I will have my fighter.

Guillows SE5a Electric Balsa Bash

The full scale specimen will be as an SE5 from 1917 and not the late war high powered SE5a.

The kit will be built as one with a British 180HP DD Wolseley Python HC engine and the plain steel UC fitted, both uncommon, yet still used in low numbers at the front line. The fitters will install an 8' propeller, instead of the 7'10” prop used with the 150HP engines.

The riggers will reduce the dihedral 2 degrees, to improve sideslip for aiming the weapon. It will also have the Vickers MG and headrest delete field mods, popular with the somewhat lightly powered SE5, because of weight, synchronized gun stoppage and rear field of view issues.

This will give the old SE5 sprightly performance and solid weaponry in battle, albeit with reduced firepower. It's not exactly a plane for the tenderfoot, but would have been be quite capable in the right hands.

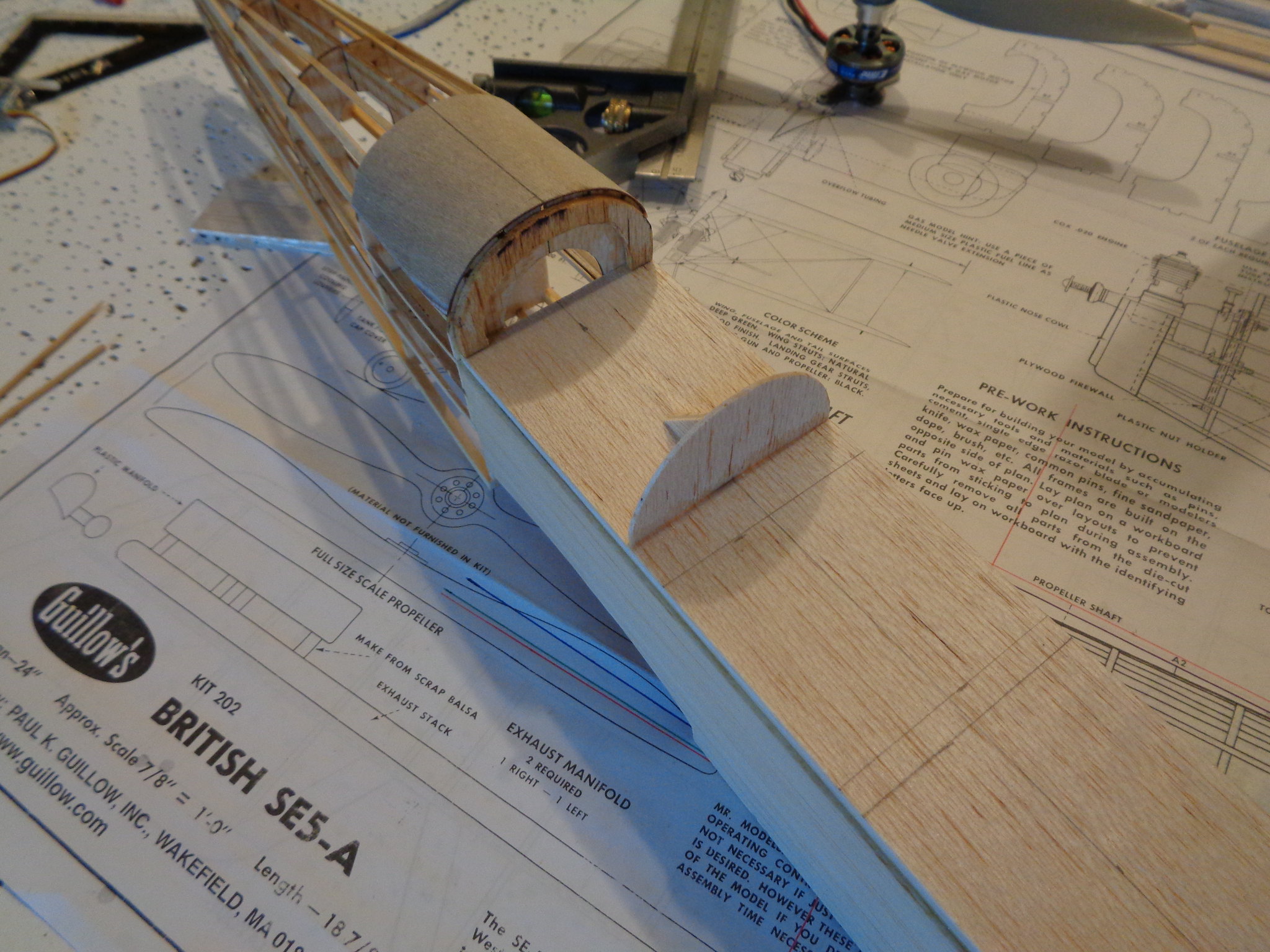

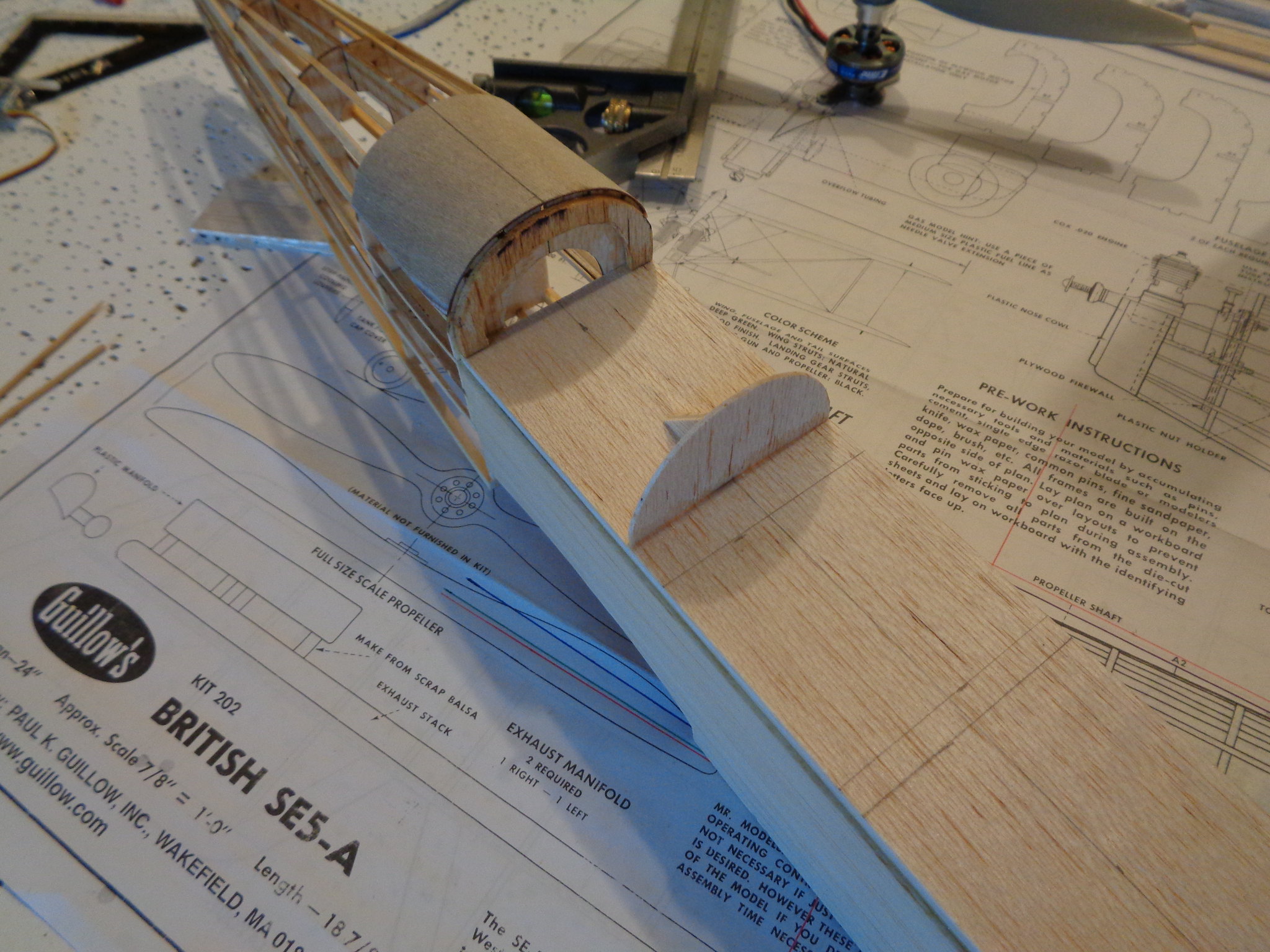

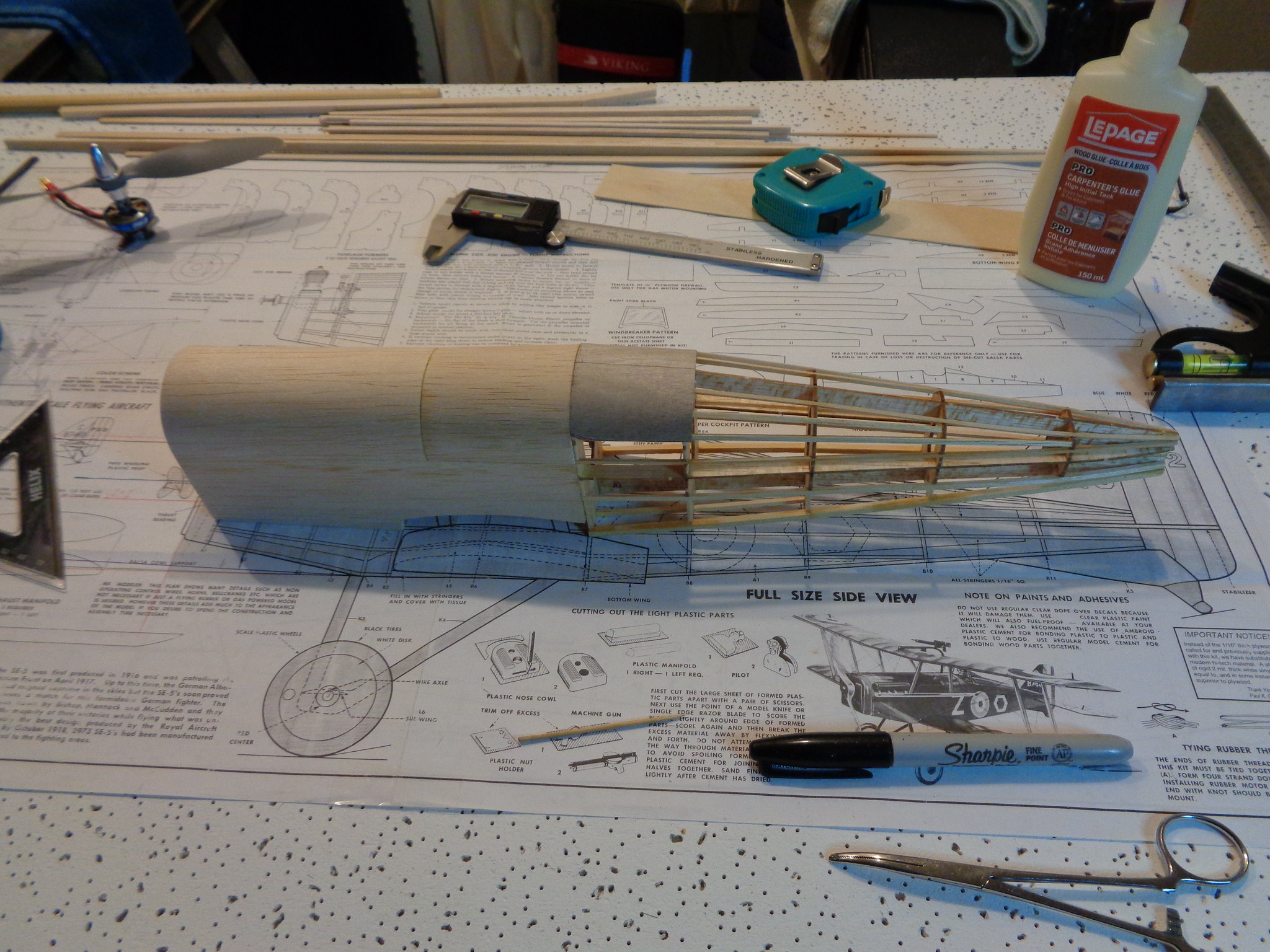

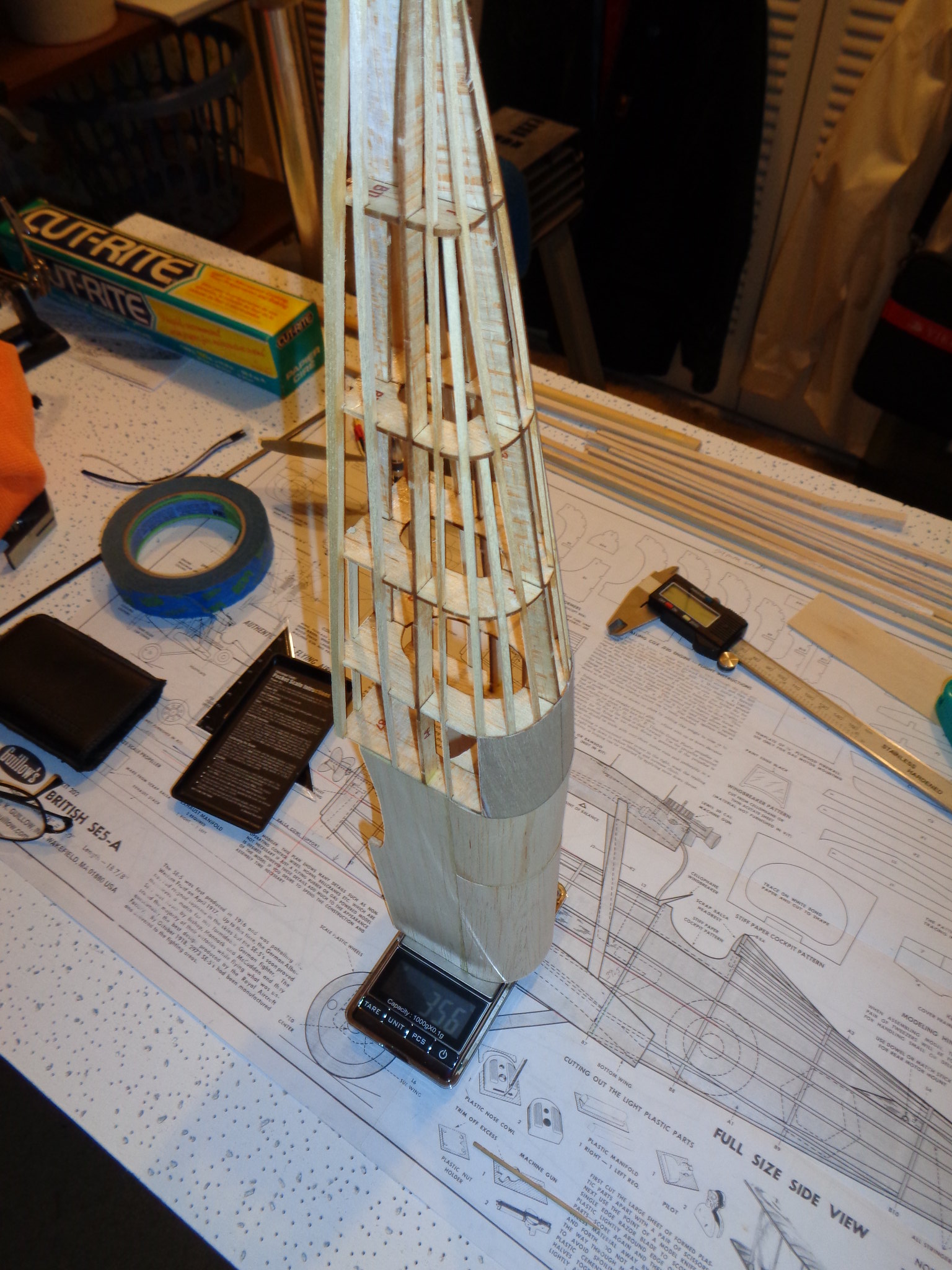

The fuselage bash:

The fuse forward of B7 will have a power channel made of laminated composite balsa foam (1mm balsa/1mm Depron/1mm balsa) and a 1mm balsa semi monocoque structural turtle deck above. The power channel will house and allow easy access to the Rx, motor, ESC, and battery change. The channel will be close to elevation scale.

The fuse from B7 and back will be fairly similar to the original, but with 3/32 lower spruce stringers, full length stringers changed to bass and a 0.4mm birch ply cockpit cover. The rear portion will have balsa foam mounts for the empennage servos.

The wings bash:

The centre sections will have 1mm bass reinforcements across the spar dihedral angles.

The lower wing will have a fuse interface with a 0.4mm ply top cover and a balsa ply (0.4mm birch/1.0mm balsa/0.4mm birch) bottom section. It will be through bolted to the power channel as a structural section using 4 x Nylon M3 screws. Note: this converts the channel section to a structural box section.

Strut mounts will be balsa ply across the struts. The struts will be carbon fibre and connected to Nylon angles. All connections will be bolted with steel M2 fasteners (no screws to pull out).

The upper wing will have balsa foam servo mounts. Lower ailerons will be connected with thin carbon/steel struts.

The empennage bash:

Basic. Convert hinged structural components to bass.

Hinges of packing tape. Painted thin acrylic for aileron lower covers.

202 SE5 Electric Balsa Bash

6 posts

• Page 1 of 1

Re: 202 SE5 Electric Balsa Bash

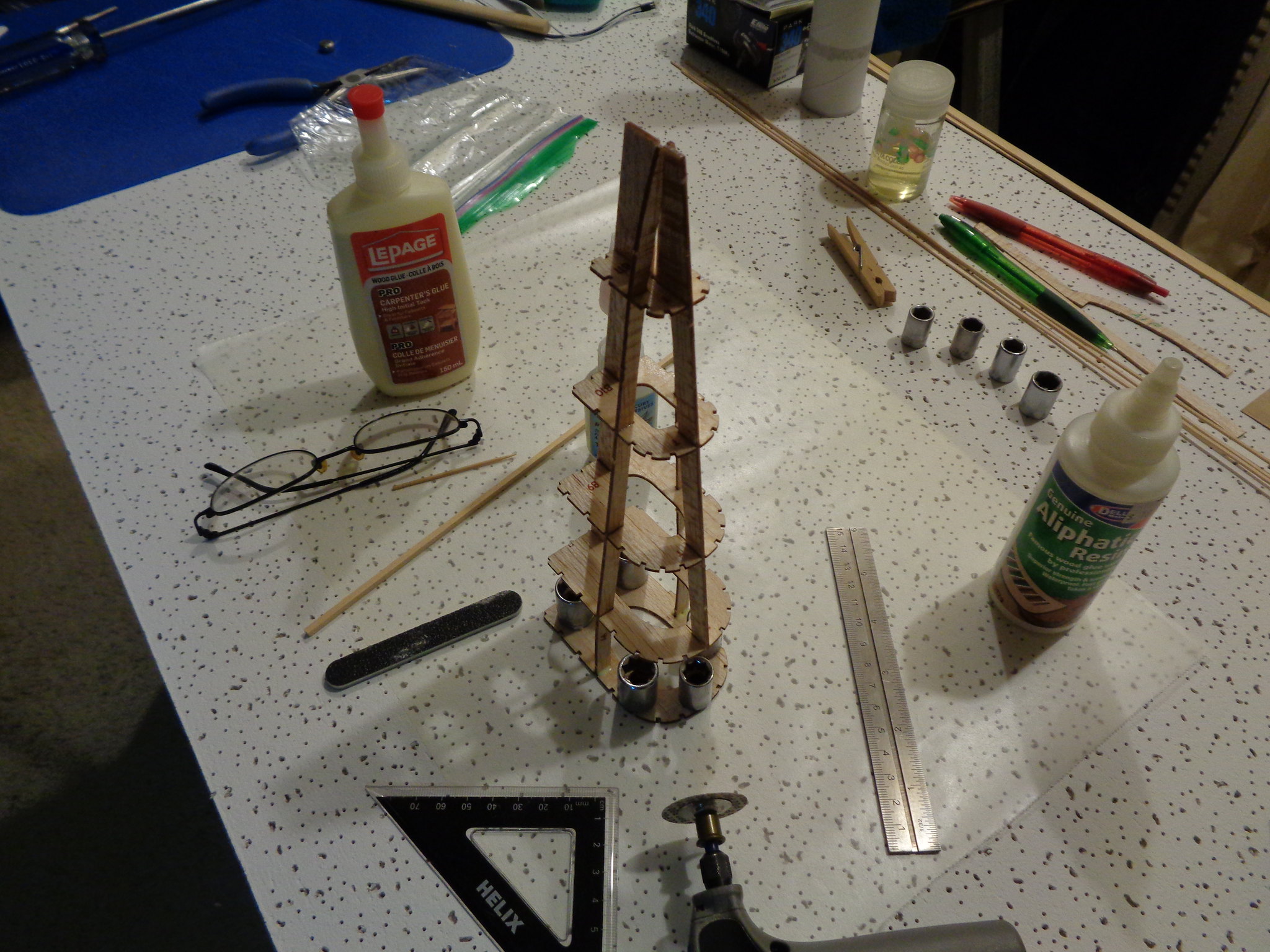

The Kit and Kabootle

SE5a

WS = 26'7” = 319”

L = 20'11” = 251”

WA = 244 sq ft

Averaged wing chord = 9.18” = 110.12”

AR = 5.8/2 = 2.9

2 blade prop (180HP) 8'

Gross weight = 1935lbs

7.93lbs/sq ft

Power off stall 43MPH

Wing Cube Load = 8.1

Fuel 375lbs = 19% gross for 150 minutes endurance

SE5 32 gallons x 8.4lbs = 269lbs

Guillows kit 202 Scale = 1/13.3

WS = 24”

L = 18+”

WA = 199 sq” = 12.84 sq dM = 1.38sq'

AWC = 8.3”

Prop = 7.2”

Target weight = 8.1 oz = 230g

1.16g/sq” = 18g/sq dM = 5.87oz/sq'

Wing Cube Load 5.0

Air frame weight...................................................................... 100g = 3.5oz

Power

E-flite Park 340 1700Kv w/mount.................................................. 28.9g

Idle current 0.72 @ 8V

Resistance 0.115

Max current 13A

145W

Castle Creations Talon 15........................................................... 7.2g

Resistance 0.045

Rampage 870mAh 2s 75C......................................................... .. 50g

18% gross for 10 min endurance

Resistance 20mOhms

Prop APC 8 x 4.7 SF.................................................................. 6.8g

Prop collet............................................................................ 7.0g

Receiver

Admiral RX600XP..................................................................... 7.0g

Servos

Hitec HS5035HD 4.5g (x 4)......................................................... 18g

Push rods/hardware.................................................................. 5g

AUW................................................................................. 229.9g = 8.12oz

Wing Cube Load = 5

SE5a

WS = 26'7” = 319”

L = 20'11” = 251”

WA = 244 sq ft

Averaged wing chord = 9.18” = 110.12”

AR = 5.8/2 = 2.9

2 blade prop (180HP) 8'

Gross weight = 1935lbs

7.93lbs/sq ft

Power off stall 43MPH

Wing Cube Load = 8.1

Fuel 375lbs = 19% gross for 150 minutes endurance

SE5 32 gallons x 8.4lbs = 269lbs

Guillows kit 202 Scale = 1/13.3

WS = 24”

L = 18+”

WA = 199 sq” = 12.84 sq dM = 1.38sq'

AWC = 8.3”

Prop = 7.2”

Target weight = 8.1 oz = 230g

1.16g/sq” = 18g/sq dM = 5.87oz/sq'

Wing Cube Load 5.0

Air frame weight...................................................................... 100g = 3.5oz

Power

E-flite Park 340 1700Kv w/mount.................................................. 28.9g

Idle current 0.72 @ 8V

Resistance 0.115

Max current 13A

145W

Castle Creations Talon 15........................................................... 7.2g

Resistance 0.045

Rampage 870mAh 2s 75C......................................................... .. 50g

18% gross for 10 min endurance

Resistance 20mOhms

Prop APC 8 x 4.7 SF.................................................................. 6.8g

Prop collet............................................................................ 7.0g

Receiver

Admiral RX600XP..................................................................... 7.0g

Servos

Hitec HS5035HD 4.5g (x 4)......................................................... 18g

Push rods/hardware.................................................................. 5g

AUW................................................................................. 229.9g = 8.12oz

Wing Cube Load = 5

- RocketRobin

- Posts: 9

- Joined: Thu Dec 12, 2013 8:40 am

Re: 202 SE5 Electric Balsa Bash

Last edited by RocketRobin on Sat Jan 25, 2020 6:54 am, edited 1 time in total.

- RocketRobin

- Posts: 9

- Joined: Thu Dec 12, 2013 8:40 am

Re: 202 SE5 Electric Balsa Bash

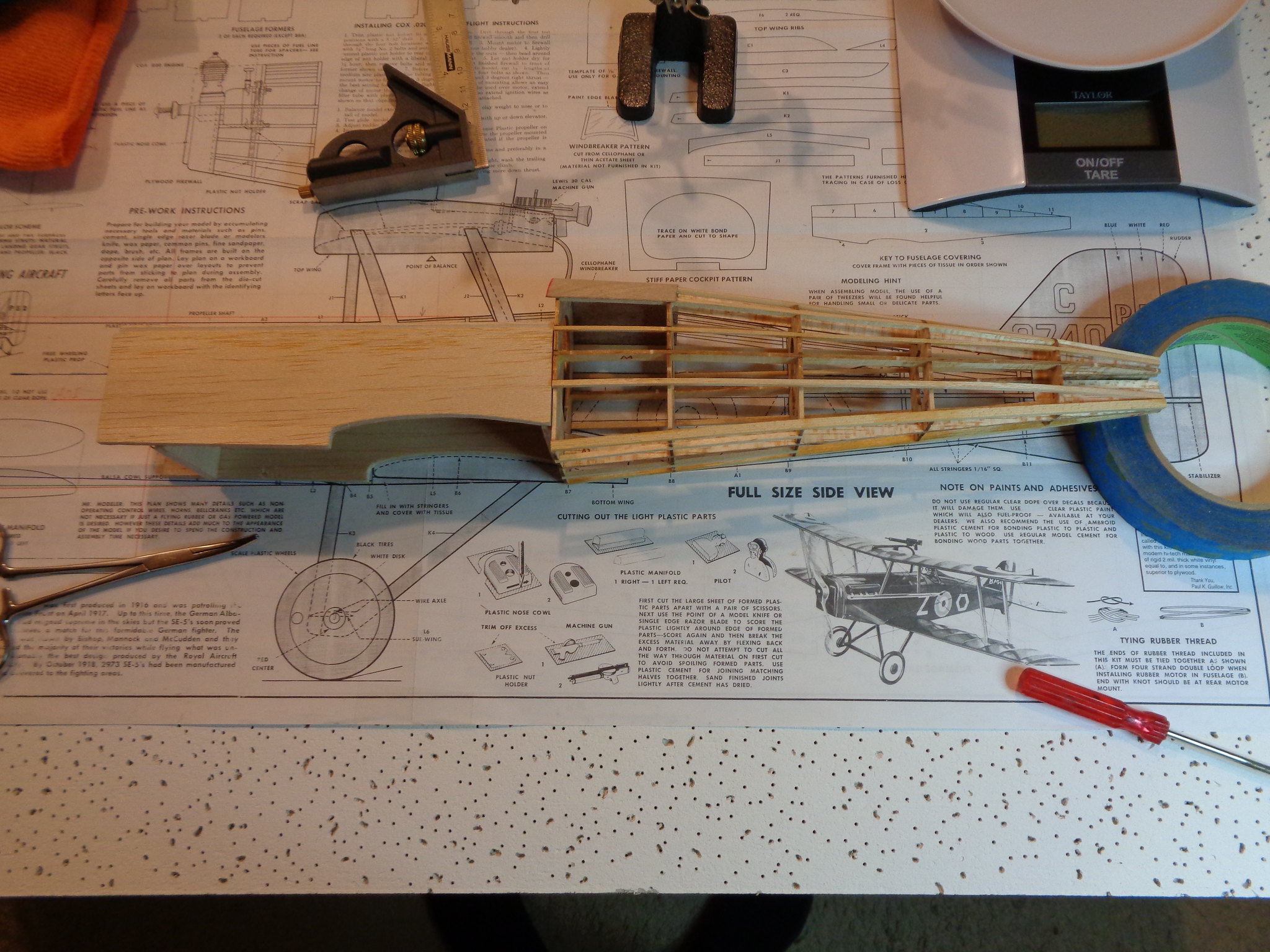

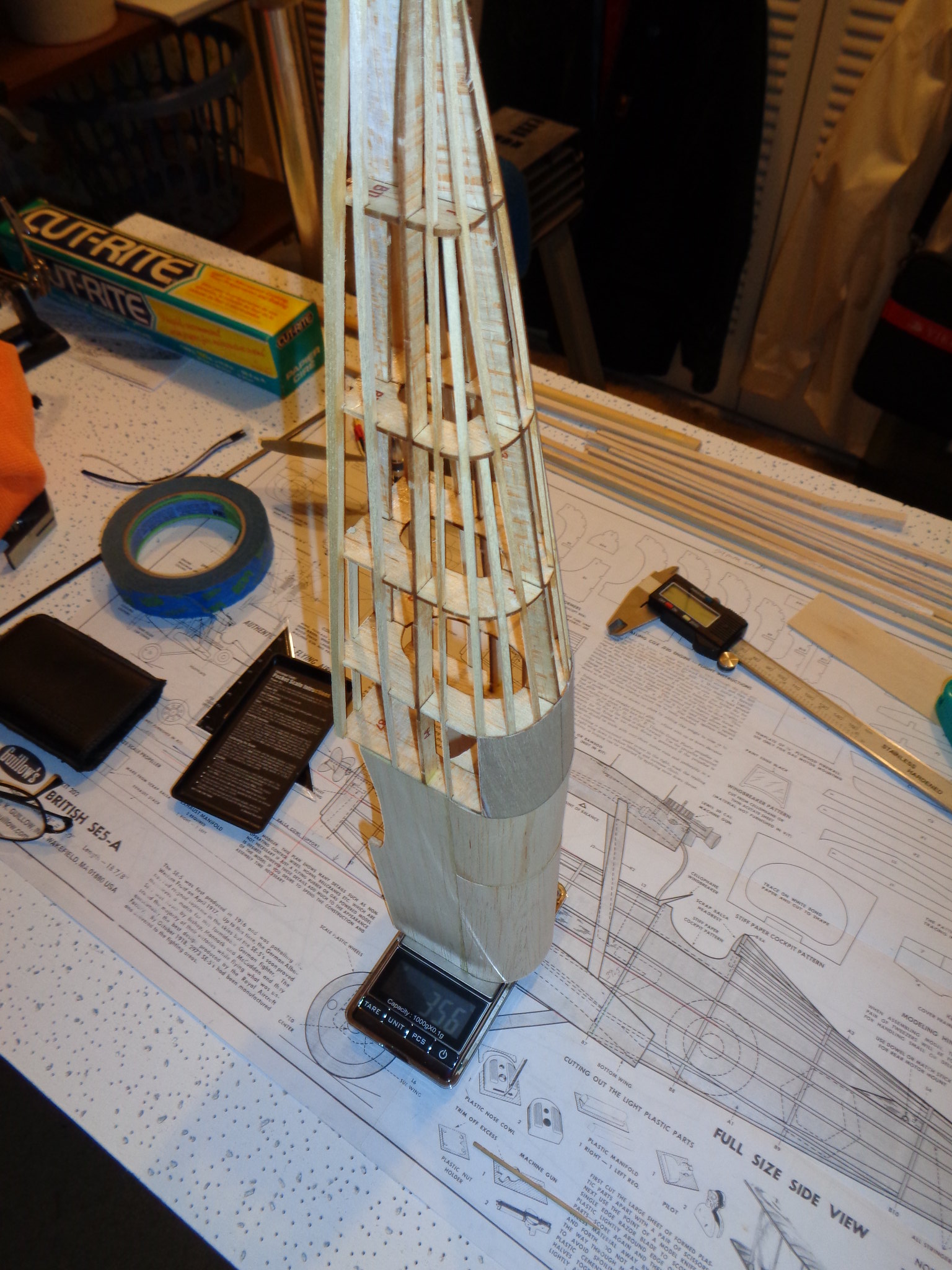

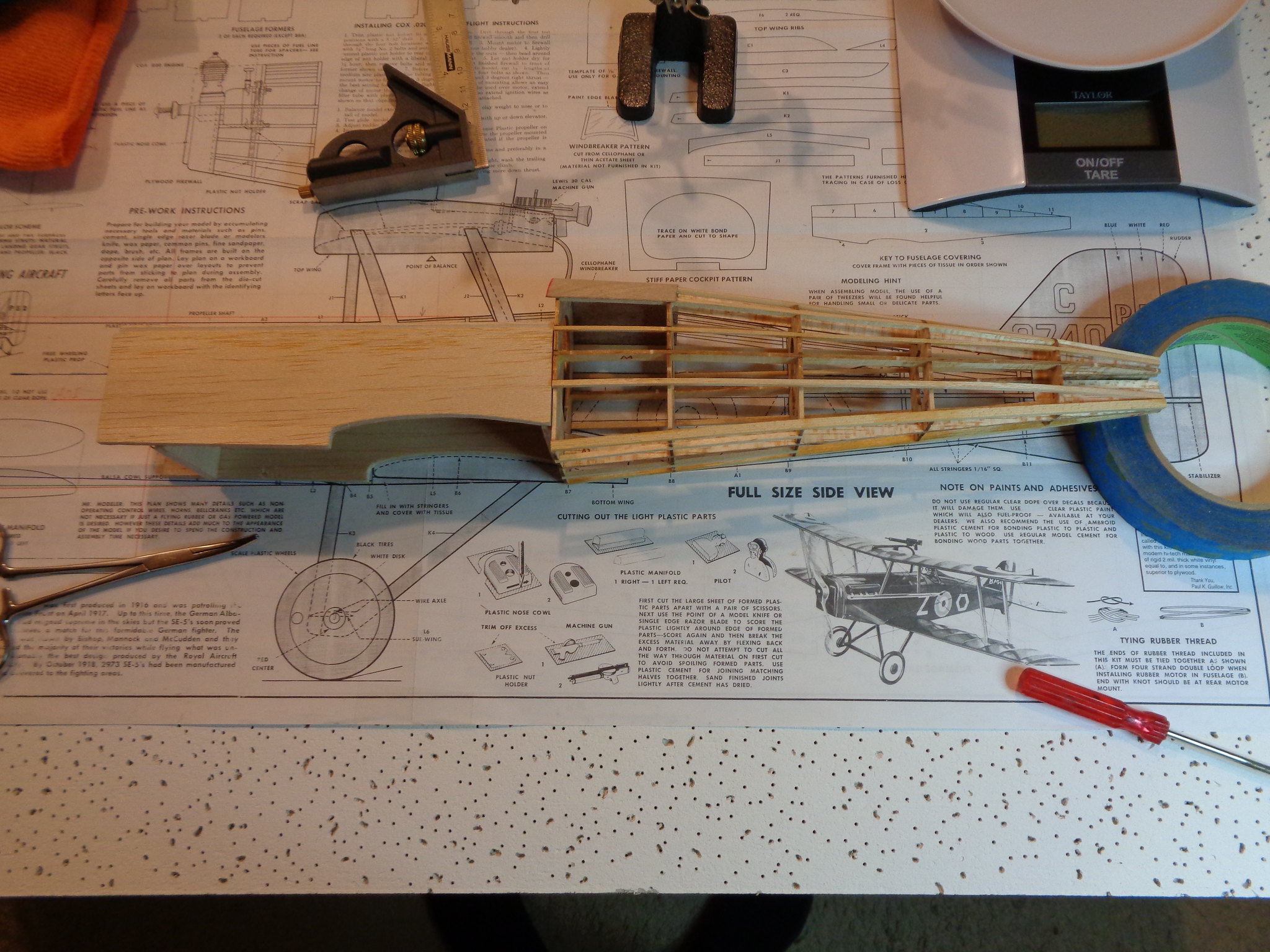

Fuse framed

Fuse Together on Plan by Sandy Scott, on Flickr

Fuse Together on Plan by Sandy Scott, on Flickr

Turtle Start by Sandy Scott, on Flickr

Turtle Start by Sandy Scott, on Flickr

Fuse Frame by Sandy Scott, on Flickr

Fuse Frame by Sandy Scott, on Flickr

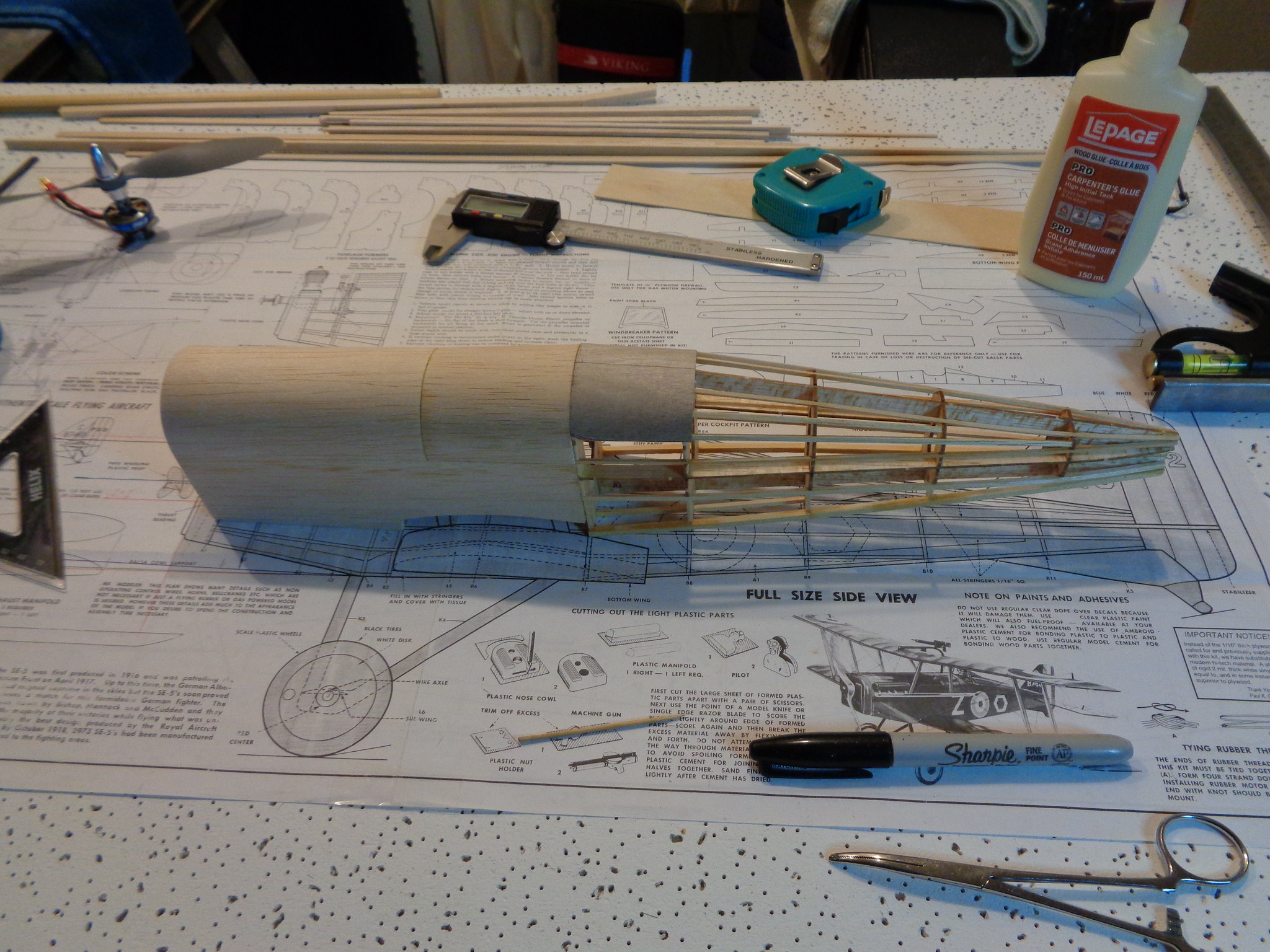

Turtle Finish by Sandy Scott, on Flickr

Turtle Finish by Sandy Scott, on Flickr

Fuse Together on Plan by Sandy Scott, on Flickr

Fuse Together on Plan by Sandy Scott, on Flickr Turtle Start by Sandy Scott, on Flickr

Turtle Start by Sandy Scott, on Flickr Fuse Frame by Sandy Scott, on Flickr

Fuse Frame by Sandy Scott, on Flickr Turtle Finish by Sandy Scott, on Flickr

Turtle Finish by Sandy Scott, on FlickrLast edited by RocketRobin on Sat Jan 25, 2020 6:59 am, edited 1 time in total.

- RocketRobin

- Posts: 9

- Joined: Thu Dec 12, 2013 8:40 am

Re: 202 SE5 Electric Balsa Bash

Careful with the weight. If it gets over 249 grams you'll have to register it!@

- kittyfritters

- Posts: 700

- Joined: Tue Jan 03, 2006 6:58 pm

- Location: California

Re: 202 SE5 Electric Balsa Bash

AUW................................................................................. 229.9g = 8.12oz

I know the fuse is really fat, but I wanted it that way. I want something sturdy to carry the lipo, which is the large mass factor.

I don't want to have to be all delicate with the plane. I want to be able to jam the battery in and fly it.

The rest of the plane will come in pretty light and it will be covered in Lightspan.

Even with the machine gun and pilot I'll be under the revenuer's limit

I know the fuse is really fat, but I wanted it that way. I want something sturdy to carry the lipo, which is the large mass factor.

I don't want to have to be all delicate with the plane. I want to be able to jam the battery in and fly it.

The rest of the plane will come in pretty light and it will be covered in Lightspan.

Even with the machine gun and pilot I'll be under the revenuer's limit

- RocketRobin

- Posts: 9

- Joined: Thu Dec 12, 2013 8:40 am

6 posts

• Page 1 of 1

Return to General Building Questions

Who is online

Users browsing this forum: No registered users and 15 guests