MODEL #402 P51D MUSTANG PICTURES

10 posts

• Page 1 of 1

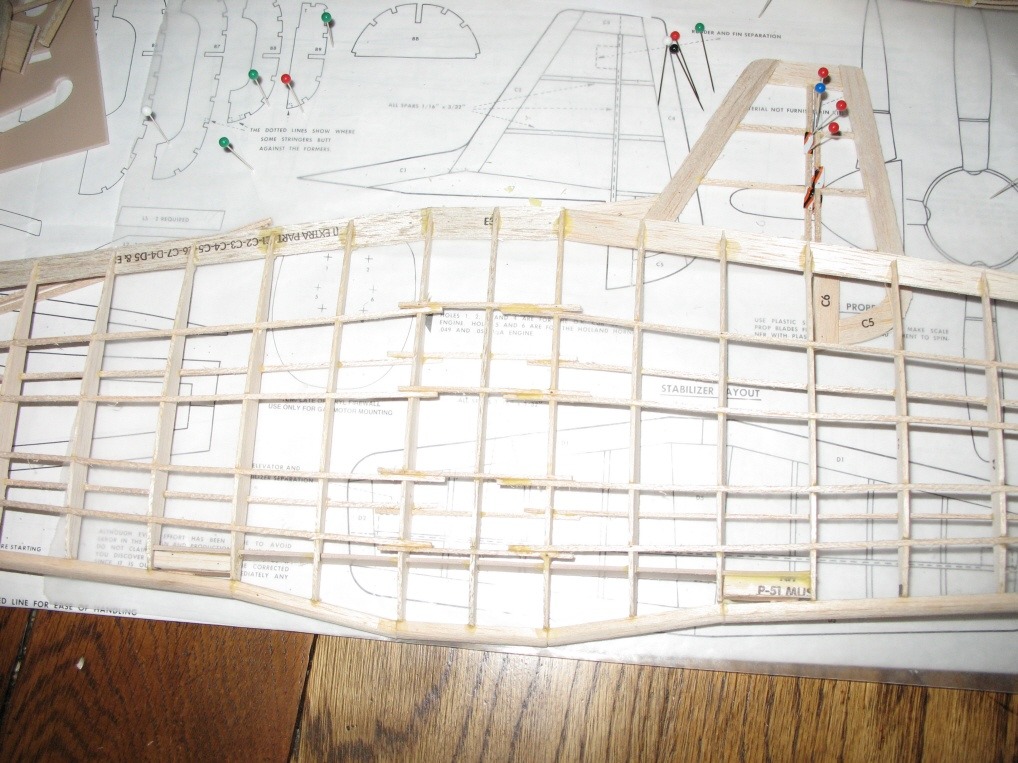

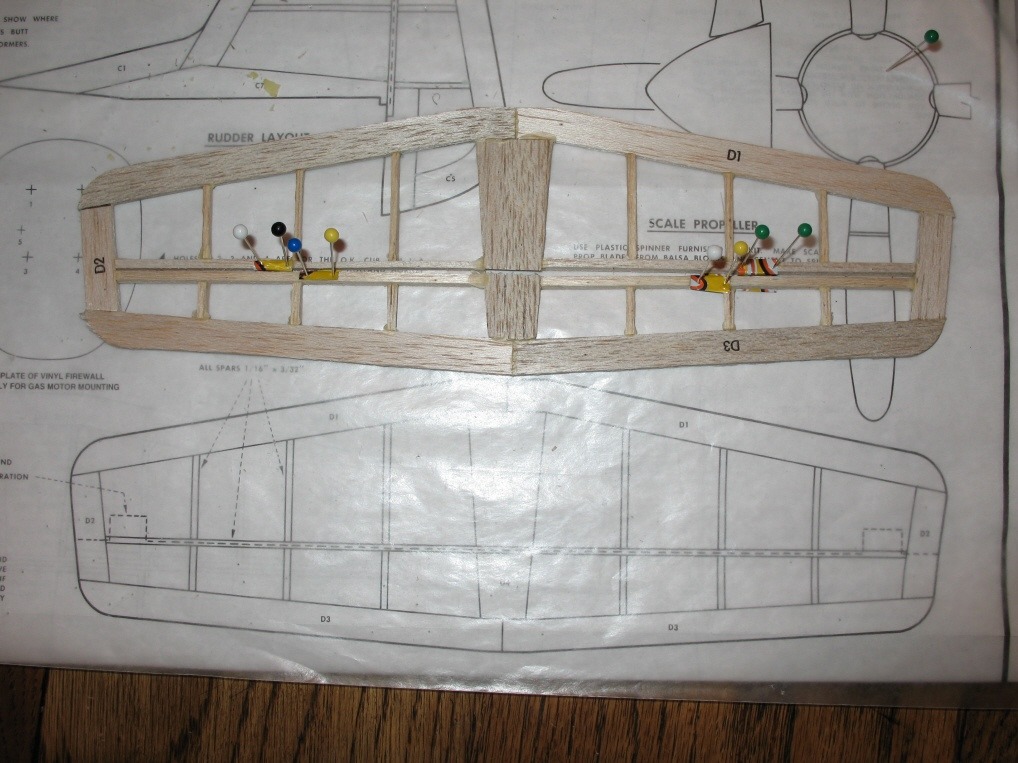

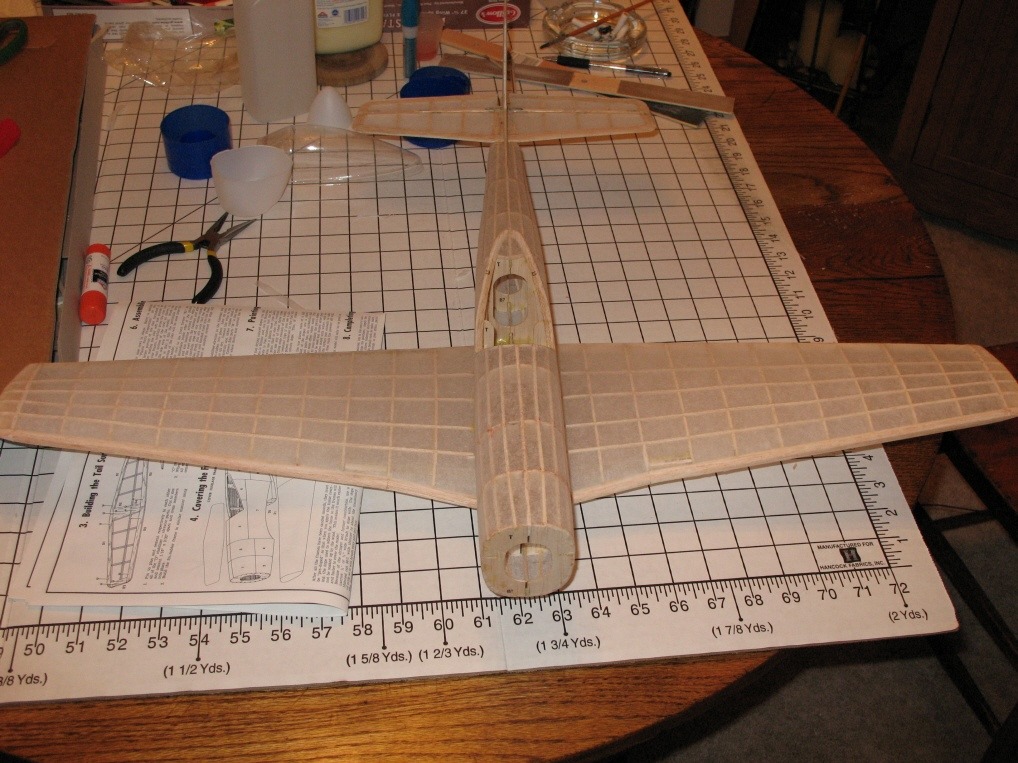

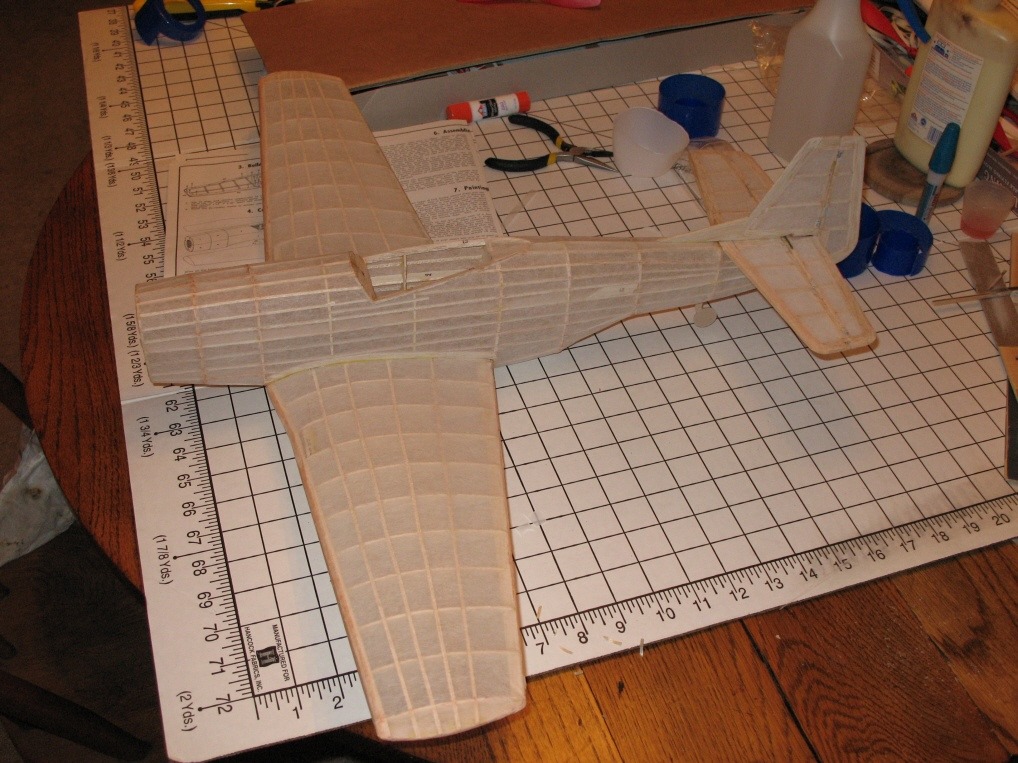

MODEL #402 P51D MUSTANG PICTURES

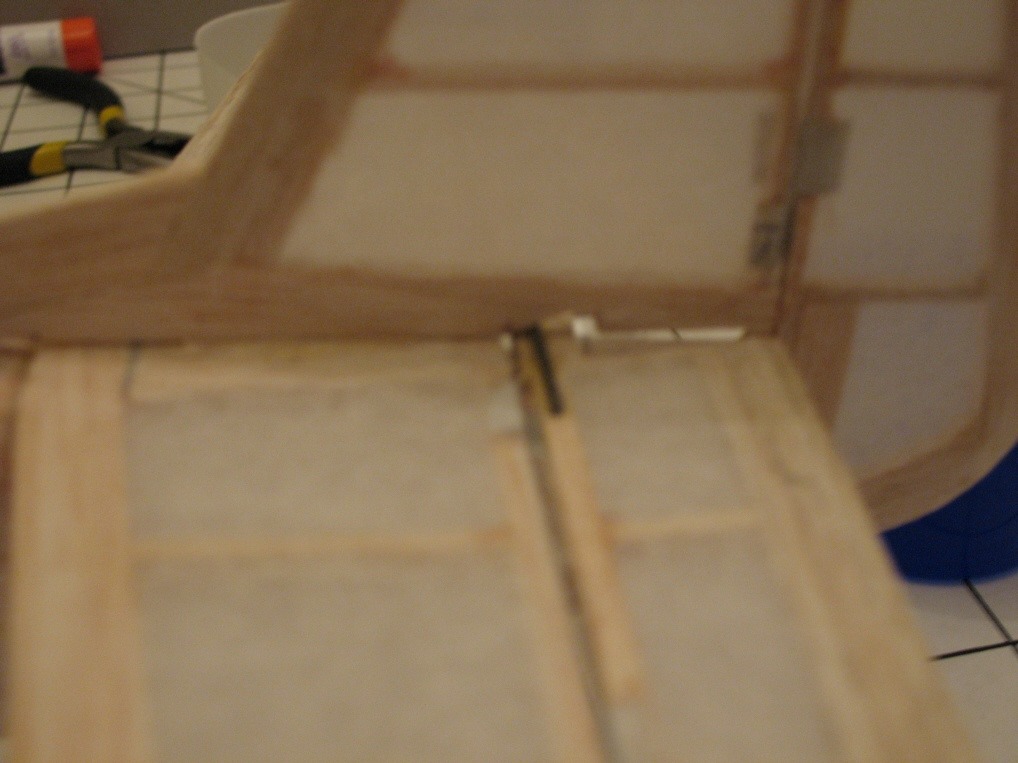

HERE ARE SOME PICTURES OF MY MODEL IN PROGRESS. I AM BUILDING THE MODEL TO FLY AND THEN DISPLAY. AS I PROGRESSED I REALIZED THAT MY BUILDING TECHNIQUES NEED A LITTLE WORK AND THE MODEL IS NOT AS EXACT AS IT COULD BE TO BE A GREAT FLYER. SO----- I HAVE COME UP WITH A FEW MODIFICATIONS TO HELP WITH FLIGHT TRIM. (CRUDE BUT HOPEFULLY EFFECTIVE) MOVEABLE RUDDER & ELEVATOR AND DETACHABLE LANDING GEAR SO FAR. THE NEXT HURDLE IS COMING UP WITH SOME SORT OF NOSEBLOCK. THE COWL DOESN'T APPEAR TO STRONG ENOUGH TO TAKE MANY TURNS ON THE RUBBER PROVIDED WITH THE KIT. I WILL POST MORE PIC'S AS THINGS PROGRESS. THANKS ALL YOU GUYS FOR THE VALUABLE INFO POSTED ON THIS WEBSITE. WILL LOOK FORWARD TO HEARING FROM YOU WITH IDEAS SUGGESTIONS ETC.

- lennyz

- Posts: 25

- Joined: Mon Jan 08, 2007 7:47 pm

- Location: WISCONSIN

cowl support

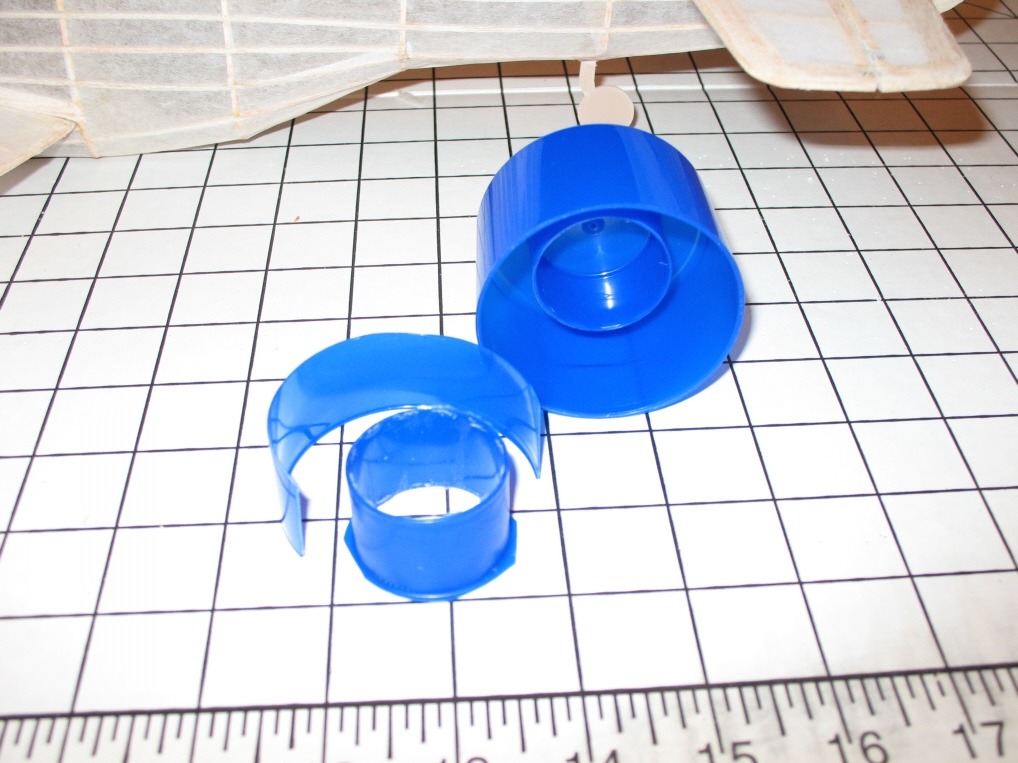

You are probably right about the cowl not being strong enough to take many rubber turns. I would think a piece of PVC pipe about 5/8" diameter would work. One end would fit nicely in the circular part of the front of the cowl and the other end butted against the front former. Cut the pipe length so the cowl slightly overlaps the former just like you normally would. You may have to reinforce the former by putting a couple of 1/8" by 1/8 sticks glued to the backside. My guess is your are going to need a big rubber motor. What's supplied in the kit will do fine for trimming flights. For longer flights, the instructions may give an alternate size rubber motor. Hope you've got a winder.

- supercruiser

- Posts: 405

- Joined: Wed Jun 15, 2005 8:47 am

I would use the plywood supplied in the kit to form the shape of the cowling and glue that to the front former. Not only will this supply a great means of attachment and cowling shaping, but the plywood is quite strong. I mean that is what you use as the "firewall" so to speak when you mount a glow or electric motor. A little predrilling etc. and as Emeril says "BAM" reinforced front former and cowling.

- moostang51

- Posts: 21

- Joined: Thu Jan 11, 2007 6:54 pm

- Location: Jackson, NJ

THE MATERIAL SUPPLIED IN THIS KIT FOR A GLOW ENGINE FIREWALL IS VINYL PRE CUT TO THE SHAPE OF THE B1 FORMER. IDELA FOR GLUING A PIECE OF PVC PIPE TO. YOU ARE RIGHT IN LINE WITH MY TRAIN OF THOUGHT ON HOW TO GET THIS DONE. THANKS

- lennyz

- Posts: 25

- Joined: Mon Jan 08, 2007 7:47 pm

- Location: WISCONSIN

You're absolutely right about the vinyl. The P-51 I built was a boxed shelf queen I purchased years ago and never built. But the vinyl was not included in this kit. It had plywood for the firewall and the tailwheel etc. Still that should do the trick for supporting the PVC tubing and preventing a cowl collapse.

- moostang51

- Posts: 21

- Joined: Thu Jan 11, 2007 6:54 pm

- Location: Jackson, NJ

If you are going to fly a Guillows model with rubber power there are many solutions to the cowl problem that give strength and adjustability without using plastic. These range from simple torque boxes and torque tubes that take the load completely off the cowl to reinforcing the plastic cowl with wooden parts. A solution using PVC pipe seems a bit extreme.

Here are some examples from past year's "G" Challenge entries. All of these models flew sucessfully:

Simple torque box on a 500 series Stuka. (H.Littman)

Torque box on a 300 Series Aeronca (H.Littman)

Torque tube on a 300 Series Cherokee (G. White)

Reinforced cowl on 300 Series Aeronca (O. Olm)

The variations are practically endless.

Howard

Here are some examples from past year's "G" Challenge entries. All of these models flew sucessfully:

Simple torque box on a 500 series Stuka. (H.Littman)

Torque box on a 300 Series Aeronca (H.Littman)

Torque tube on a 300 Series Cherokee (G. White)

Reinforced cowl on 300 Series Aeronca (O. Olm)

The variations are practically endless.

Howard

- kittyfritters

- Posts: 700

- Joined: Tue Jan 03, 2006 6:58 pm

- Location: California

10 posts

• Page 1 of 1

Return to General Building Questions

Who is online

Users browsing this forum: Bing [Bot] and 20 guests