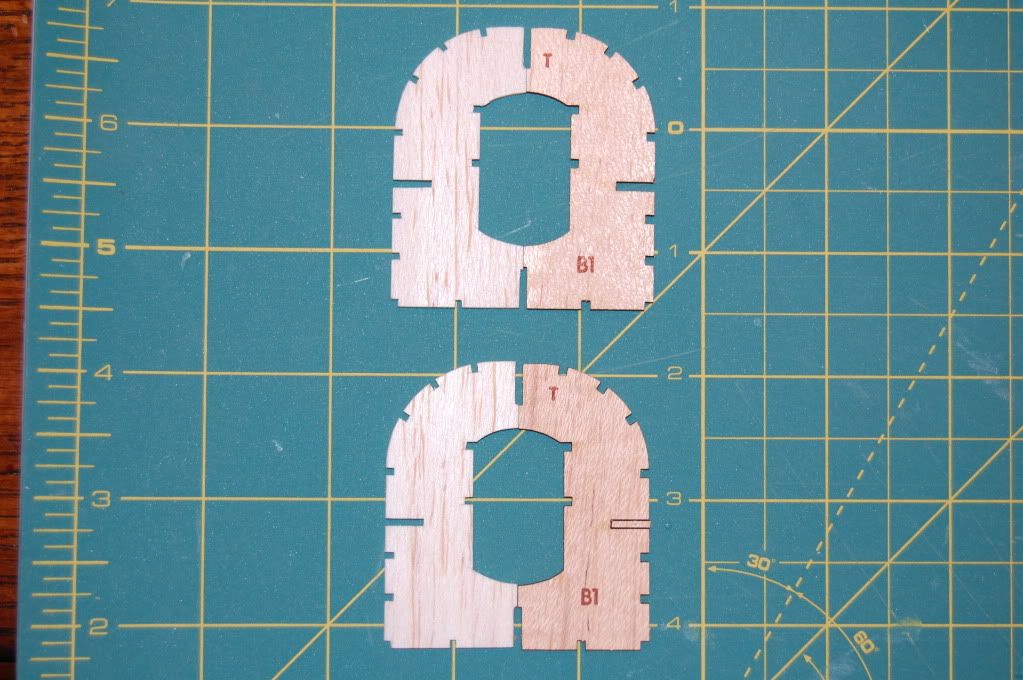

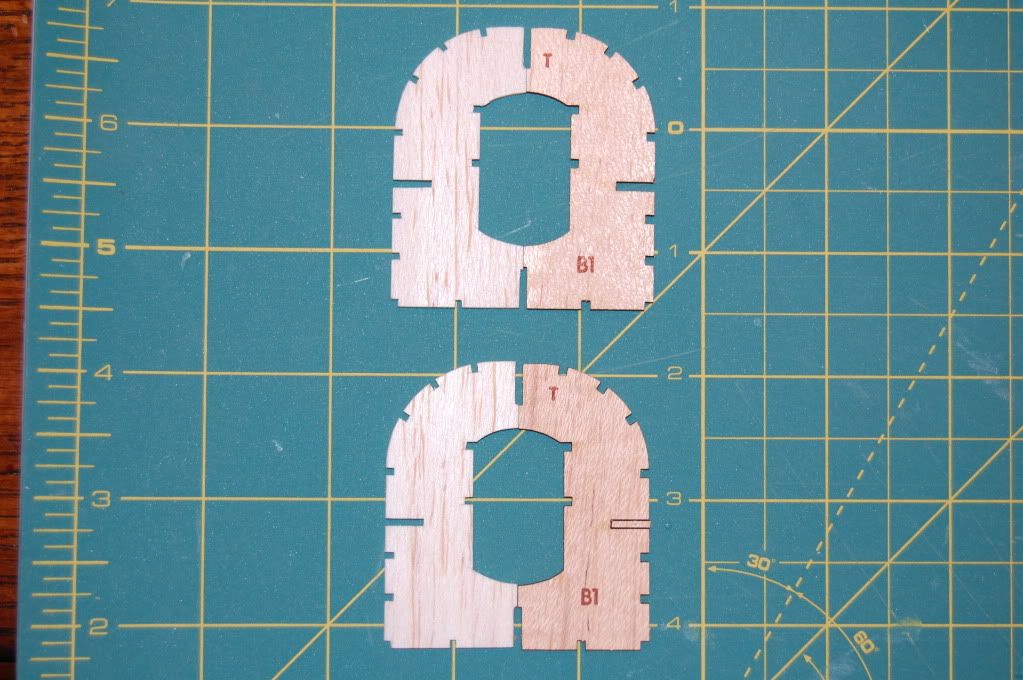

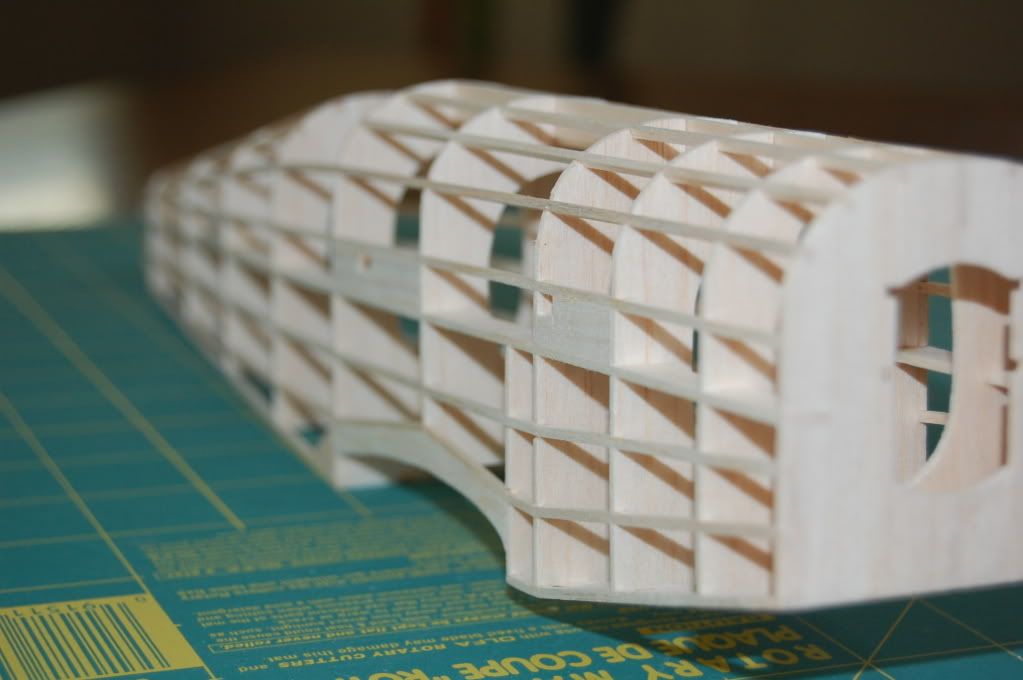

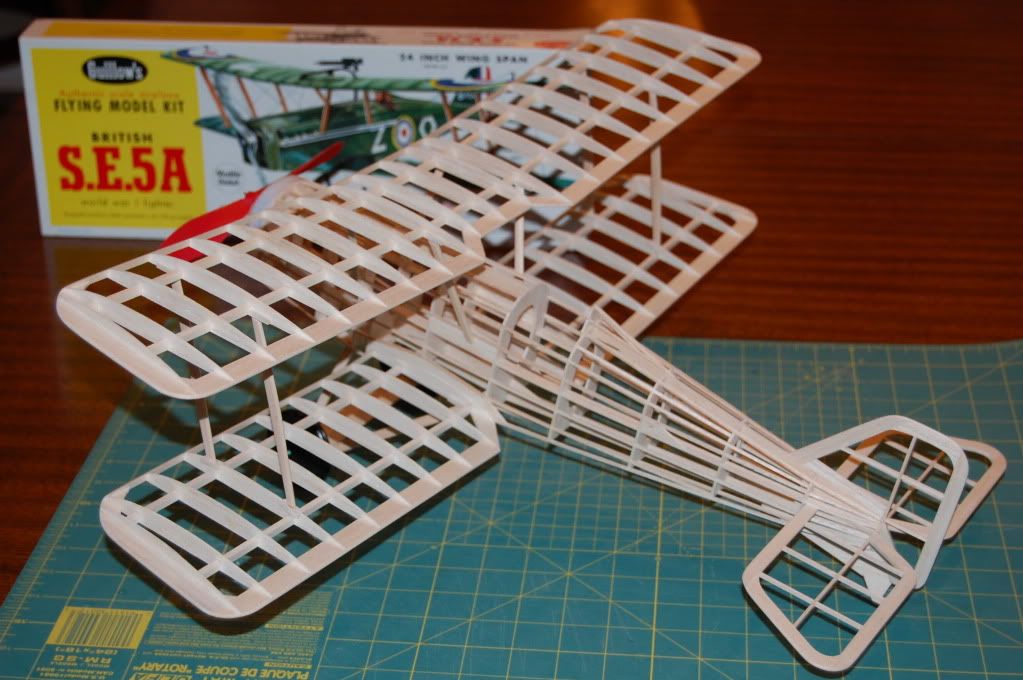

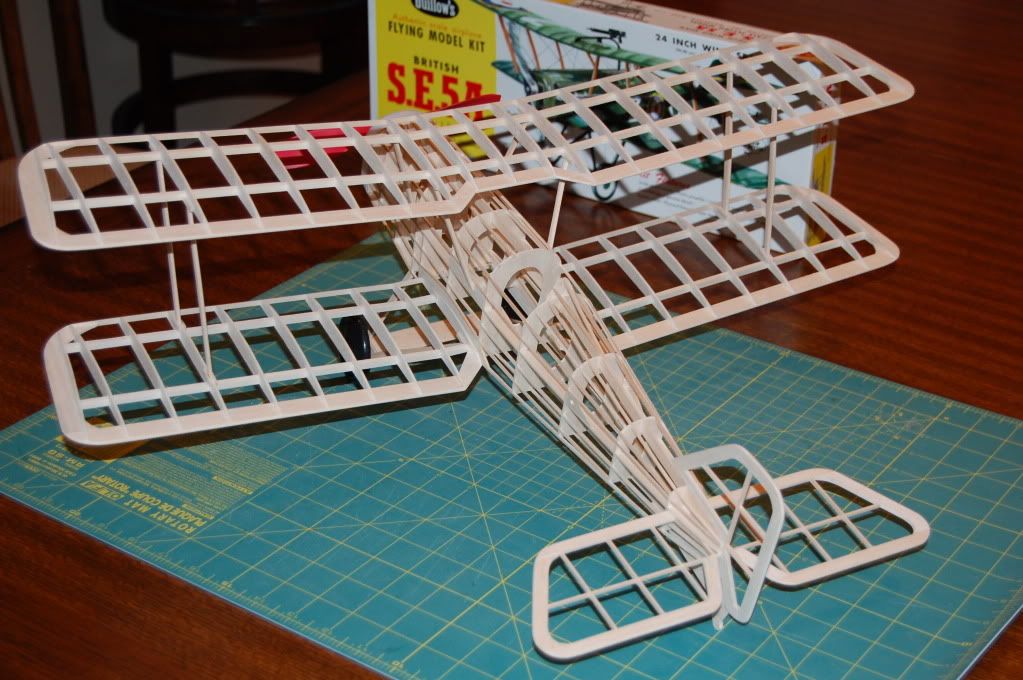

My cut is not too bad compared to the perfect Laser cut part

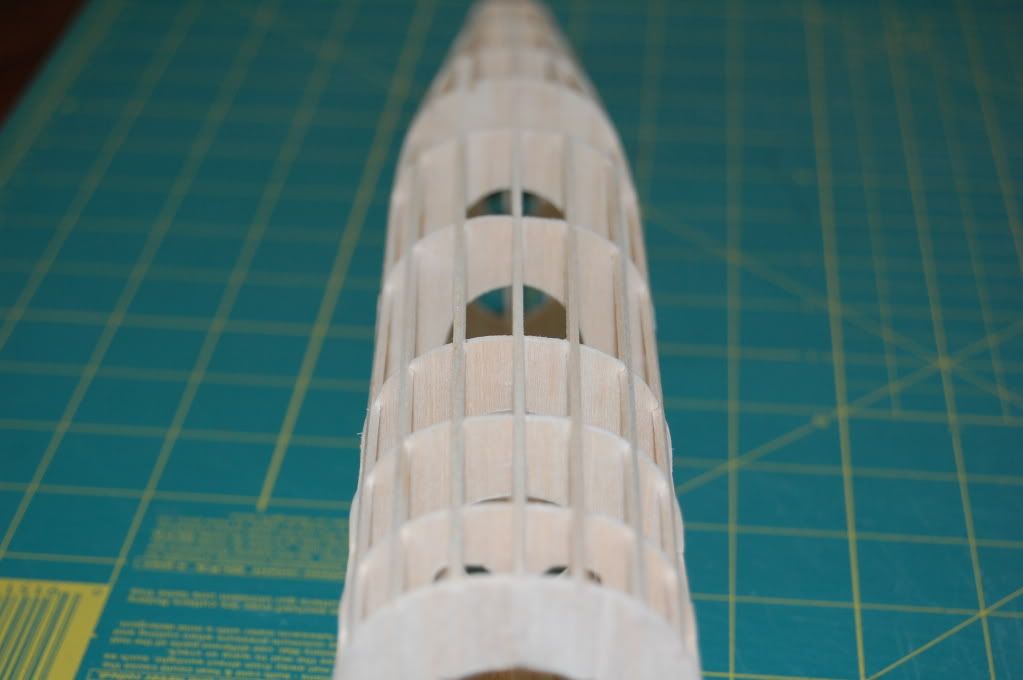

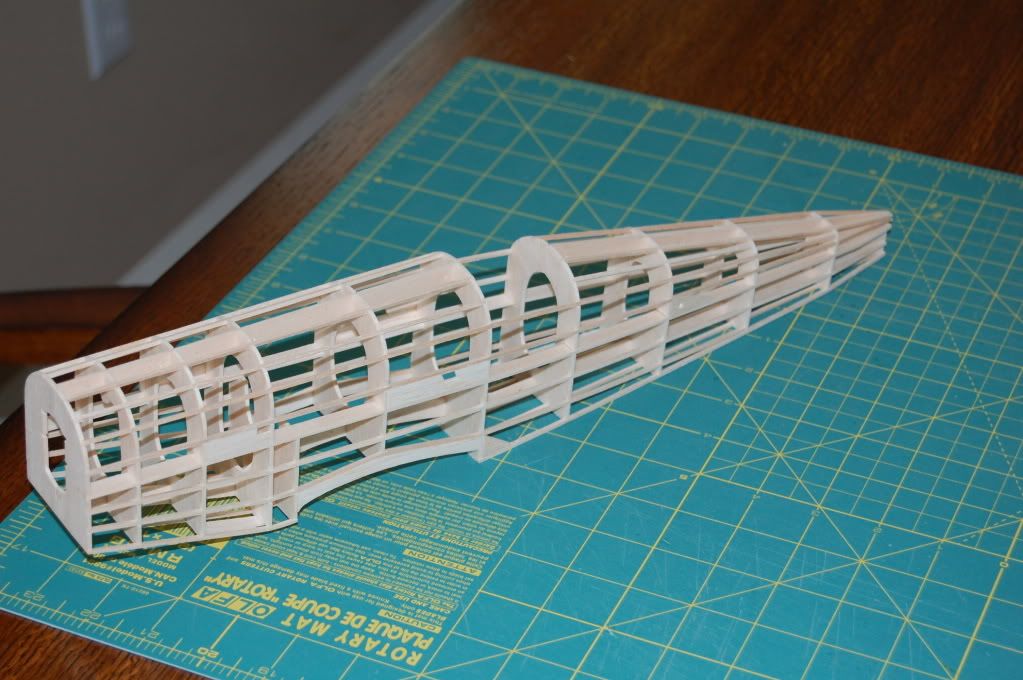

Here is the weight comparison between my parts and the laser cut part.

Return to General Building Questions

Users browsing this forum: Bing [Bot] and 36 guests