Me and several of the guys here at the Guillow's Forum had a discussion

recently about converting Guillow's planes in general to U-Control. Most

of the larger planes come with the parts, (bellcrank, wing fence, pushrods,

nuts, bolts, screws, washers, etc) to make the plane fly the circle. The

little ones however are more about rubber or 1/4a (.010, .020 COX) freeflight.

The 500 series planes have "destructions" for the old "fishing pole" circle,

where it's more about centrifical force than anything else. (always thought

it looked dangerous, a nitro fueled spinning prop, at the engd of only one

string...) Anyway, I thought it would be far more interesting to convert a

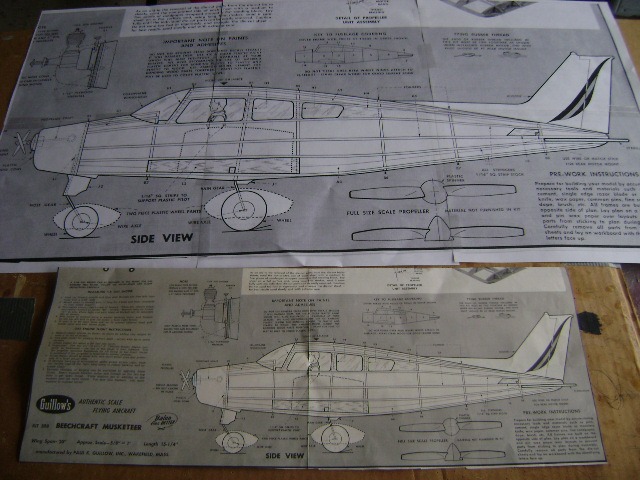

Guillow's plane that was never designed for U-Control over to circular flight.

So here we go...

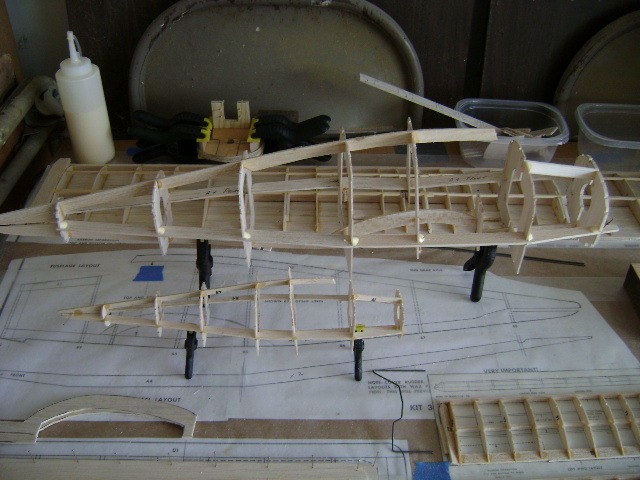

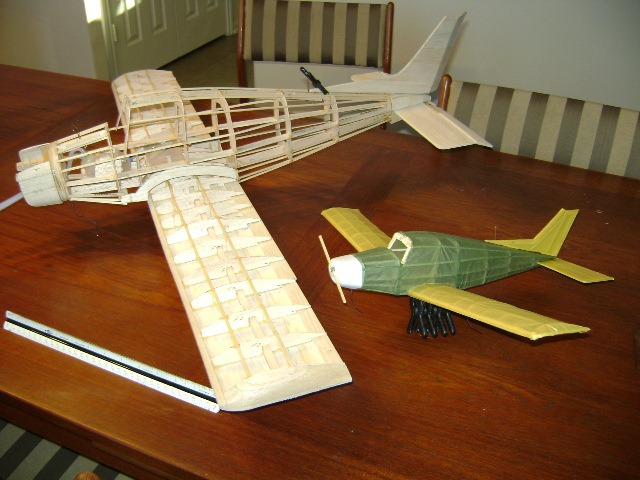

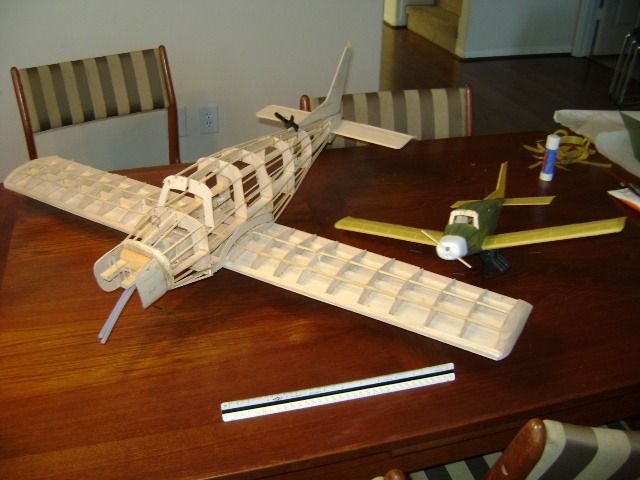

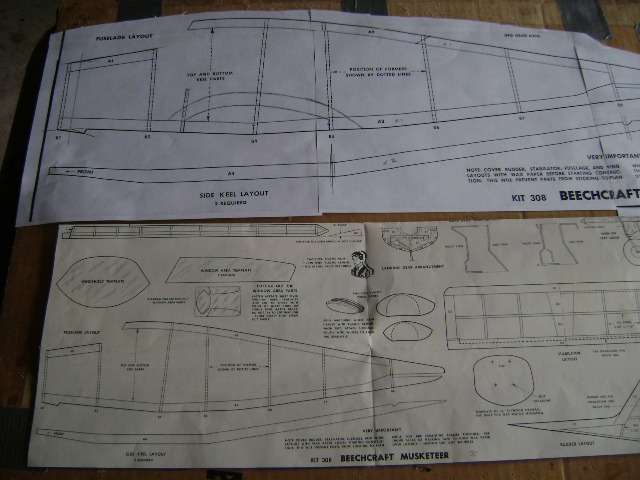

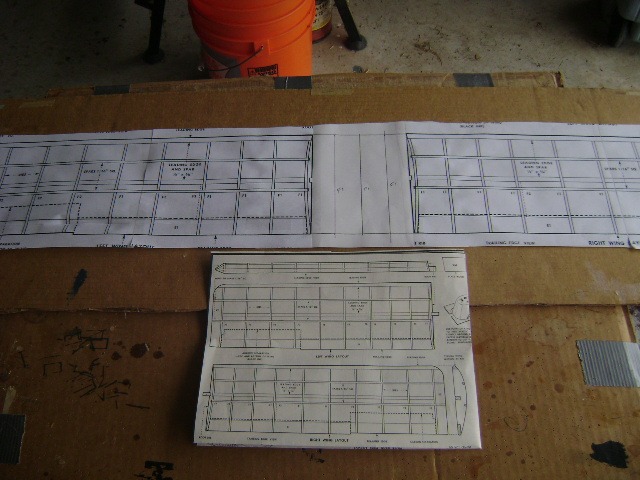

I'm building one out of the kit box, and the other is double size. Kit

is 20" wingspan, the big dog is 40" wings...

Rubber power on the little one, .09 U-Control on the big. (rubber power

is code for throw it once, and hang it on the ceiling...)

I scored a whole bunch of ESAKI tissue in all colors on sale for 5 bucks

a box from A to Z Supply, so the little feller will be green and yellow

tissue, no paint. (I think...) The big guy will be painted silkspan.

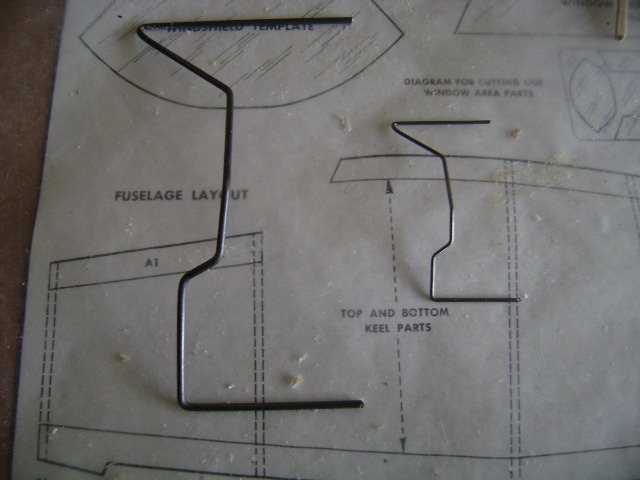

The little one has a two piece wing, but I re-engineered the big one

with a one piece wing, thus the changed lower keel you see on the big one.

I will admit that I've fallen in love with the lines of

this fuse. Coming from a warbird guy, this is big!