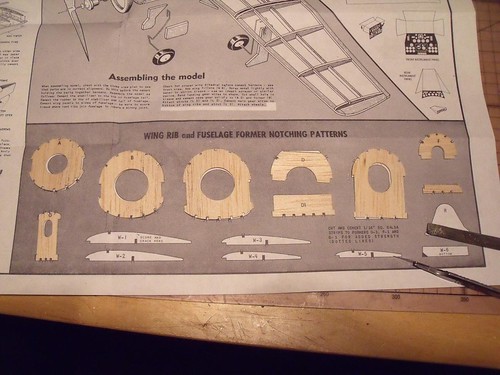

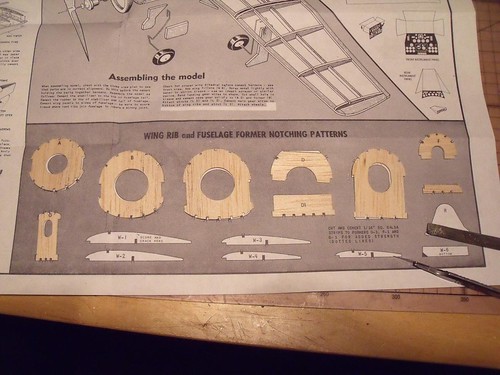

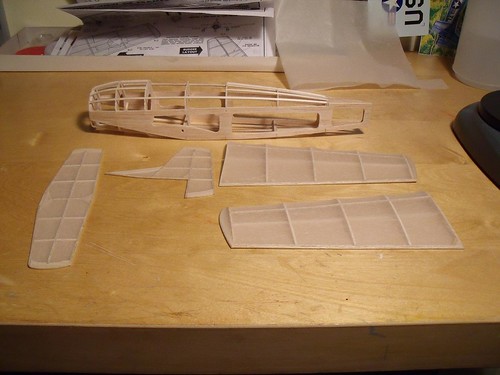

The B sheet formers have been notched to the plan. Not having the notches die cut in some ways makes this kit superior than others since you can make the notches a good size and nice and tight to the stringers.

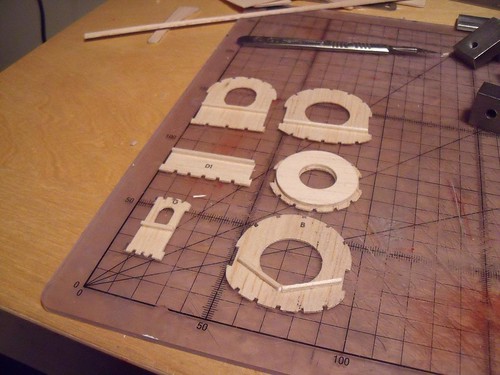

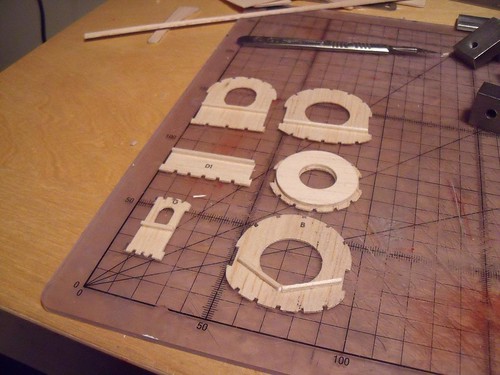

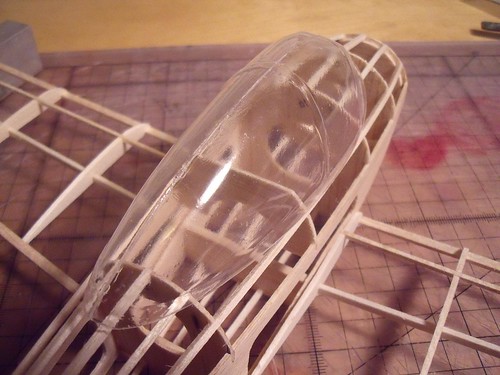

I've strengthened up all of the formers where the grain is verical including cutting a round strengthener for former "A". These will add little weight but will make the whole thing a lot more robust during construction and will help the model survive to odd dink.

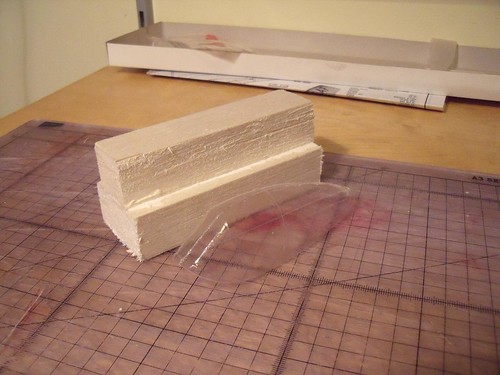

I did not use the stringers in with the kit for the fuselage. They are quite light but very stiff, which makes them very valuable for other projects as fin and tailplane leading edges and for wing spars for example. New stringers were made by cutting 1/16" strips from some 8.5 lb balsa sheet.

I also added a couple of stiffners between the formers A and B from 1/16" x 1/4 strip. At the end of the day I'll be adding noseweight here anyhow so I might as well make the weight serve some structural purpose.

The construction was a little tricky to ensure that that the fuselage was nice and straight but I think that it turned out ok.