i remember one night i put it on my night stand before bed, and it somehow fell of in the middle of the night. i ended up waking up and steping on it, and had a heck of a time fixing the wing on that. a

the only thing i can complain about is how terrable the stringers on it (1/16"). they are so heavy and dense ill just use different ones. i dont think guillows would replace them.

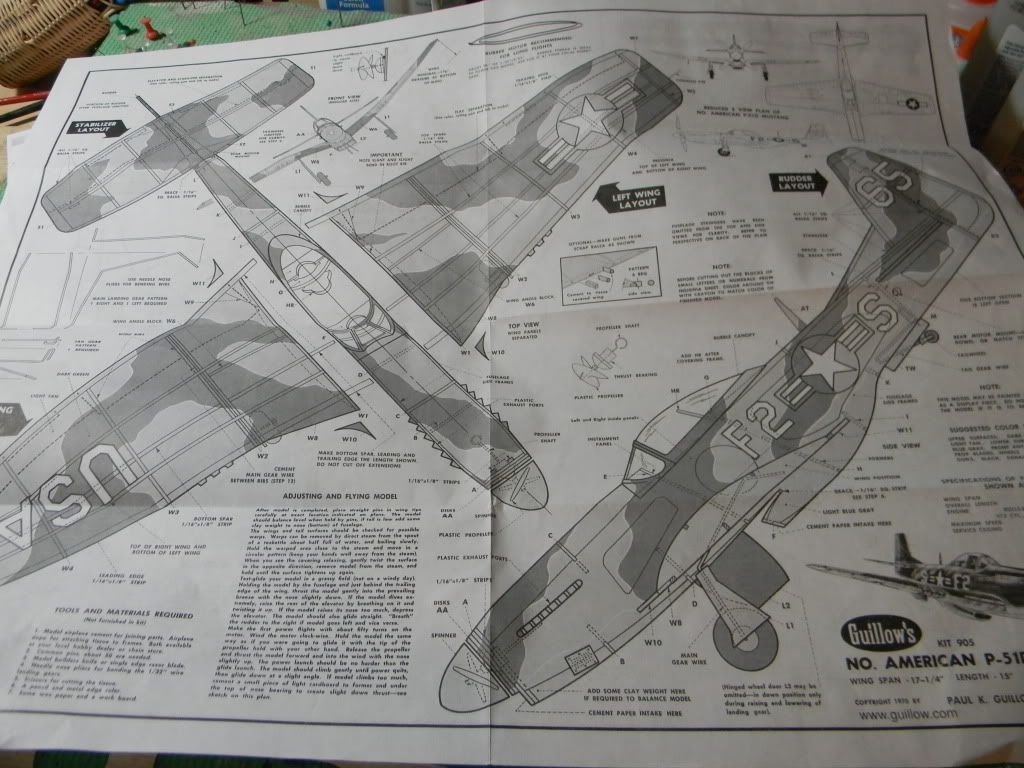

i was thinking rubber FF on this one. i think it will be a nice flyer, and a good challenge. i was also thinking gray easy built tissut lite.

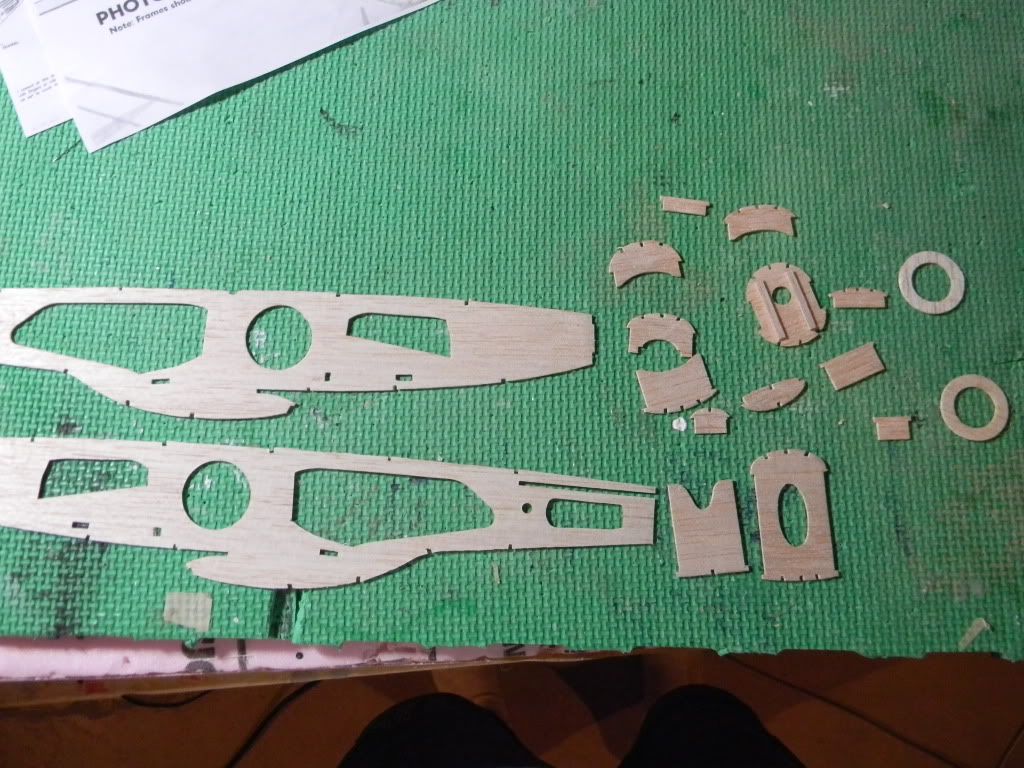

fuse parts cut out and ready to go-

all the other parts have been bagged. i think you can see the stringers there. you can tell how bad they are. esp. for a model this fragile. all the other parts were nice, and the die cuts were lovely.

nice plans on this. they have changed since i last built them, so hats off to guillows for some updates...

fuse beggining to take shape.

i really try to keep a close eye on it to make sure its nice and straight. i like to use rubber bands to hold it steady while glue drys. you can minipulate the way the fuse bends by angling the rubber band towards one end of the fuse rather than the other side, thus creating a diagonal in the rubber band. works well for me.

here, i show the fuse parts. the last time, i did not do such a great job cutting out all of the notches. i have gotten better...